IACM-DI8P-IOL /IACM-DO8P-IOL

Superisys

| Availability: | |

|---|---|

| Quantity: | |

| Minimum Order Quantity | one |

| Price | Large quantity price negotiable |

| Delivery Time | 5-8 work days |

| Stock | In Stock |

| Description | 16 digital input/output M8 series, IOLINKslave station |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| IO-LINK | Polarity | Model | ||

| Class A | PNP | IACM-DI8P-IOL-M8 | IACM-DI8N-IOL-M8 | IACM-DIO8P-IOL-M8 |

| NPN | IACM-DO8P-IOL-M8 | IACM-DO8N-IOL-M8 | IACM-DIO8N-IOL-M8 | |

| Product description | IO-LINK slave module, 8 x port | |||

| IO-LINK slave module 8x port IP67 protection class | M8,3pin hole holder, A code | |||

| IO-Link slave parameters | ||||

| Number of IO-Link ports | 1x Device | |||

| lO-Link deals with data length | Two input bytes | Two output bytes | Two input bytes | |

| Two output bytes | ||||

| Minimum cycle period | 3 ms | |||

| Digital input and output parameters | ||||

| Number of inputs and outputs | 8 inputs | 8 Outputs | 8 Way adaptive | |

| Rated operational voltage | 18…30V DC | |||

| Maximum load current (sensor) | 200 mA | — | 200 mA | |

| Maximum load current (actuator) | -- | 500 mA | 500 mA | |

| Total current UI | <1.6A | — | <1.6A | |

| Total current UO | — | <2.5A | <2.5A | |

| Module indicator light | ||||

| IO-LINK RUN | Green: communication is not connected | |||

| Green flash: communication is normal | ||||

| Red: communication interruption | ||||

| I/o | Green: the channel signal is normal | |||

| Red: port failure | ||||

| Basic parameter | Shell material | PA6+GF | ||

| Shell color | Black | |||

| level of protection | IP67, epoxy full potting | |||

| Boundary dimension | 155mm×53mm×28.7mm | |||

| Weight | 227g | |||

| Operating temperature | -25℃…70℃ | |||

| Storage/transport temperature | -40℃…85℃ | |||

| Operation humidity | 5%…95% | |||

| Store/transport humidity | 5%95% | |||

| Operating atmospheric pressure | 80KPa…106KPa | |||

| Store/transport atmospheric pressure | 80KPa…106KPa | |||

| IVO mouth tightening torque | M12:0.5Nm | |||

| Application environment | In accordance with EN-61131 | |||

| Vibration measurement | Comply with IEC60068-2 | |||

| Impact test | Comply with IEC60068-27 | |||

| Free drop test | Comply with IEC60068-32 | |||

| Electromagnetic Compatibility (EMC) | Comply With IEC61000-4-2,-3,-4 | |||

| Authentication | CE,RoHS | |||

| Mounting hole Specification | Ø4.3mm×4 | |||

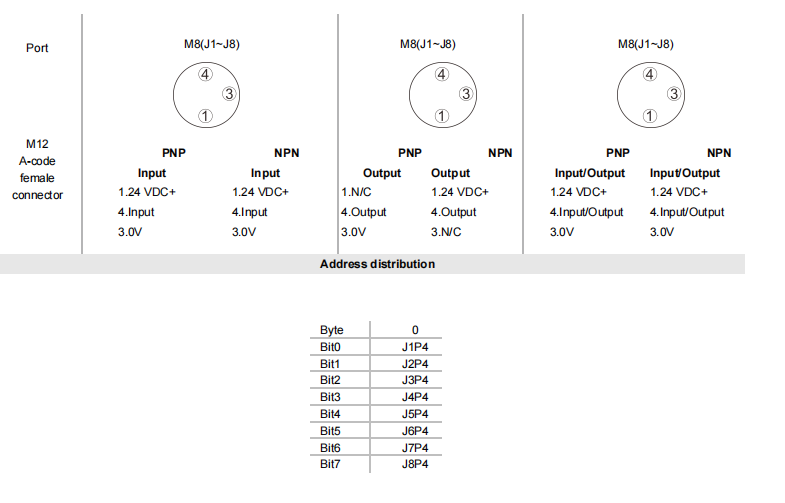

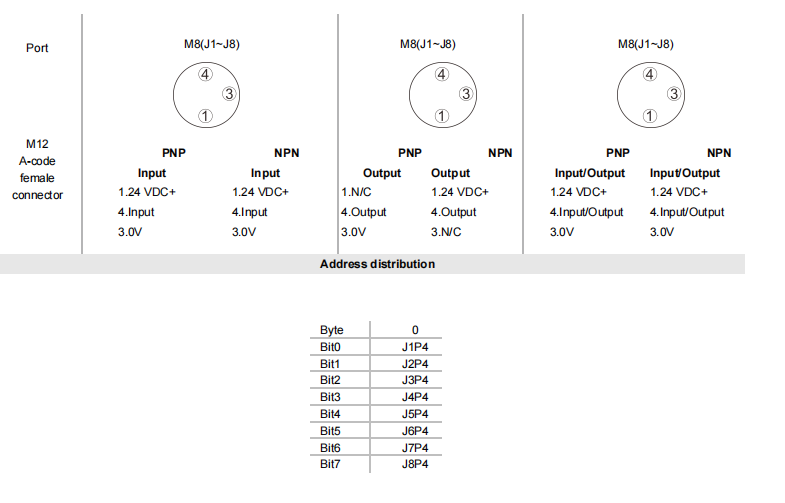

| Pin definition | ||||

| ||||

| Minimum Order Quantity | one |

| Price | Large quantity price negotiable |

| Delivery Time | 5-8 work days |

| Stock | In Stock |

| Description | 16 digital input/output M8 series, IOLINKslave station |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| IO-LINK | Polarity | Model | ||

| Class A | PNP | IACM-DI8P-IOL-M8 | IACM-DI8N-IOL-M8 | IACM-DIO8P-IOL-M8 |

| NPN | IACM-DO8P-IOL-M8 | IACM-DO8N-IOL-M8 | IACM-DIO8N-IOL-M8 | |

| Product description | IO-LINK slave module, 8 x port | |||

| IO-LINK slave module 8x port IP67 protection class | M8,3pin hole holder, A code | |||

| IO-Link slave parameters | ||||

| Number of IO-Link ports | 1x Device | |||

| lO-Link deals with data length | Two input bytes | Two output bytes | Two input bytes | |

| Two output bytes | ||||

| Minimum cycle period | 3 ms | |||

| Digital input and output parameters | ||||

| Number of inputs and outputs | 8 inputs | 8 Outputs | 8 Way adaptive | |

| Rated operational voltage | 18…30V DC | |||

| Maximum load current (sensor) | 200 mA | — | 200 mA | |

| Maximum load current (actuator) | -- | 500 mA | 500 mA | |

| Total current UI | <1.6A | — | <1.6A | |

| Total current UO | — | <2.5A | <2.5A | |

| Module indicator light | ||||

| IO-LINK RUN | Green: communication is not connected | |||

| Green flash: communication is normal | ||||

| Red: communication interruption | ||||

| I/o | Green: the channel signal is normal | |||

| Red: port failure | ||||

| Basic parameter | Shell material | PA6+GF | ||

| Shell color | Black | |||

| level of protection | IP67, epoxy full potting | |||

| Boundary dimension | 155mm×53mm×28.7mm | |||

| Weight | 227g | |||

| Operating temperature | -25℃…70℃ | |||

| Storage/transport temperature | -40℃…85℃ | |||

| Operation humidity | 5%…95% | |||

| Store/transport humidity | 5%95% | |||

| Operating atmospheric pressure | 80KPa…106KPa | |||

| Store/transport atmospheric pressure | 80KPa…106KPa | |||

| IVO mouth tightening torque | M12:0.5Nm | |||

| Application environment | In accordance with EN-61131 | |||

| Vibration measurement | Comply with IEC60068-2 | |||

| Impact test | Comply with IEC60068-27 | |||

| Free drop test | Comply with IEC60068-32 | |||

| Electromagnetic Compatibility (EMC) | Comply With IEC61000-4-2,-3,-4 | |||

| Authentication | CE,RoHS | |||

| Mounting hole Specification | Ø4.3mm×4 | |||

| Pin definition | ||||

| ||||

8-channel digital I/O

Configurable as PNP/NPN inputs or outputs, enabling flexible connectivity to sensors, valves, and relays.

M8 connector standard

Rugged M8 ports ensure vibration-resistant connections, reducing downtime in high-motion industrial settings.

Plug-and-Play Integration

Automatic detection of IO-LINK controllers eliminates manual addressing, speeding deployment.

Industrial Durability

IP67-rated aluminum housing resists dust, moisture, and chemical splashes.

Reduces wiring complexity

Single-cable IO-LINK technology transmits power, data, and configuration, reducing installation costs by 40%.

Real-time diagnostics

Monitor device health and signal status over the IO-LINK network for predictive maintenance.

Global Compliance

Meets CE, RoHS and IEC 61000-6-2/4 electromagnetic compatibility and industrial safety standards.

This IO-LINK AIO module optimizes automation in the following areas:

Automotive: Connect welding sensors and robotic grippers via an IO-LINK-enabled PLC.

Food and Beverage: Control filling nozzles and sanitary valves in washdown environments.

Pharmaceutical: Monitor blister packaging sensors and conveyor speed control.

Material Handling: Manage photoelectric sensors on AGVs (Automated Guided Vehicles).

Energy Industry: Interface with pressure sensors in oil/gas pipeline monitoring systems.

8-channel digital I/O

Configurable as PNP/NPN inputs or outputs, enabling flexible connectivity to sensors, valves, and relays.

M8 connector standard

Rugged M8 ports ensure vibration-resistant connections, reducing downtime in high-motion industrial settings.

Plug-and-Play Integration

Automatic detection of IO-LINK controllers eliminates manual addressing, speeding deployment.

Industrial Durability

IP67-rated aluminum housing resists dust, moisture, and chemical splashes.

Reduces wiring complexity

Single-cable IO-LINK technology transmits power, data, and configuration, reducing installation costs by 40%.

Real-time diagnostics

Monitor device health and signal status over the IO-LINK network for predictive maintenance.

Global Compliance

Meets CE, RoHS and IEC 61000-6-2/4 electromagnetic compatibility and industrial safety standards.

This IO-LINK AIO module optimizes automation in the following areas:

Automotive: Connect welding sensors and robotic grippers via an IO-LINK-enabled PLC.

Food and Beverage: Control filling nozzles and sanitary valves in washdown environments.

Pharmaceutical: Monitor blister packaging sensors and conveyor speed control.

Material Handling: Manage photoelectric sensors on AGVs (Automated Guided Vehicles).

Energy Industry: Interface with pressure sensors in oil/gas pipeline monitoring systems.