What is IO-Link

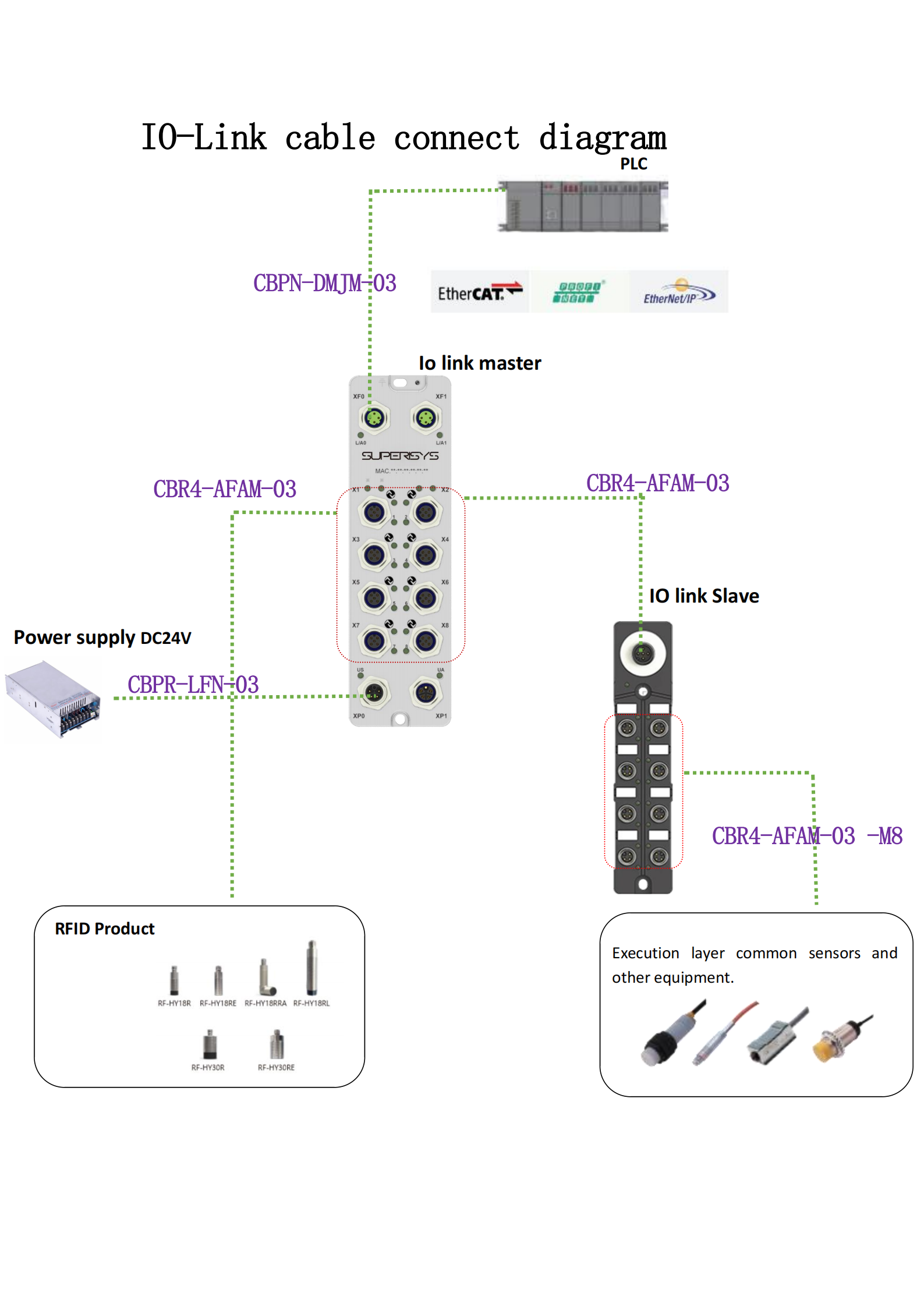

IO-Link is an open, short-distance, point-to-point standard that connects sensors/actuators to an IO-Link master over ordinary unshielded 3-wire cabling; the master then bridges this data into the control system (e.g., a PLC) via common fieldbus/industrial Ethernet networks. Beyond cyclic process values, IO-Link also exchanges device parameters and diagnostic events, enabling remote setup and fast troubleshooting. In practice, this makes the “last meter” of the machine more transparent and configurable—cutting integration effort/costs and simplifying device configuration. Choose Superisys IO-Link Modules — Compatible (plug-and-play with major PLCs, fewer gateways), Rugged (IP67 machine-mount), Self-diagnostic (port-level alarms & remote parameterization). Launch faster, cut downtime. Talk to an expert.

With Superisys IO-Link, You can benefit from

Compatible

Simplify wiring and dramatically reduce costs. Superisys IO-LINK uses standard M8/M12 four-wire cables for direct point-to-point connections. A single IO-LINK master module can connect up to 16 devices and seamlessly integrate with mainstream buses such as PROFINET, EtherNet/IP, and EtherCAT, simplifying PLC design.

Rugged

IP67 protection grade, aluminum alloy shell and epoxy full-split filling process, fearless of humid, dusty and welding industrial environment

Self-diagnostic

Port-level alarms (short/over-current/open), remote parameter changes, and IODD-based auto-download on device swap help you find faults fast, speed changeovers, reduce MTTR, and support predictive maintenance. The result is faster commissioning, simpler maintenance, fewer failures, and lower total cost.

Application - What can Superisys IO Link module be used for?

Comfortably handling various coatings ranging from small to large products, its rich product lineup contributes to the automation of the coating process.

Machine-side I/O island

Mount an IP67 IO-Link master on the machine; use Class A/B ports to connect sensors and valve manifolds, and uplink directly to major PLC/industrial Ethernet (Compatible). Shorter runs and cleaner wiring (Rugged), plus port-level alarms and remote parameterization for faster changeovers and troubleshooting (Self-diagnostic). Machine-side IO—faster commissioning, fewer cables, less downtime.

Modular conveyors (warehousing & in-plant logistics)

Modularize your line—plug, run, and scale with lower TCO. Deploy one master per conveyor/functional segment with M12 plug-and-play, integrating quickly with PLC/WCS (Compatible). Reliable in dust/washdown (Rugged), with faults pinpointed to port/segment and remote threshold tuning to reduce false reads (Self-diagnostic).

Robot EOAT & onboard I/O

Smart EOAT & onboard IO—lighter wiring, quicker changeovers, higher uptime. Mount the master near the end effector or vehicle; Class B single-cable power + comms drives valve manifolds/grippers and ties into existing controls (Compatible). Handles vibration/oil (Rugged) and offers hot-swap auto parameter download to cut changeover time and MTTR (Self-diagnostic).

Superisys IO Link module Advantages

Cost

Efficiency

Simplifies wiring and reduces installation expenses, offering a cost-effective alternative to traditional I/O modules while ensuring reliable system performance.

Intelligent Management

Supports smart parameter configuration and remote diagnostics, enabling real-time monitoring, quick adjustments, and minimized downtime for efficient operations.

Reliable Integration

Provides stable, anti-interference communication with multi-speed options, seamlessly connecting to Profinet, EtherNet/IP, and Modbus TCP for mainstream PLC compatibility.

Why Choose Us

Proven Reliability & Robust Tech

In-house anti-interference + high-speed algorithms, validated under vibration/EMI/weld spatter to maximize uptime.

Full-stack IO-Link, Globally Compliant

Master/Device/I/O portfolio; direct PROFINET/EtherCAT/EtherNet/IP; IO-Link v1.1.x, CE/FCC/RoHS, IP67.

Quality Delivery & Responsive Support

Related Product

Related Blogs

Keep in Touch With Us

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob: +86-13971499887

E-mail: jayne@superisys.com.cn

LF RFID Read/Write

LF RFID Read/Write  HF RFID Read/Write

HF RFID Read/Write  UHF RFID Read/Write

UHF RFID Read/Write

LF RFID Tag

LF RFID Tag  HF RFID Tag

HF RFID Tag  UHF RFID Tag

UHF RFID Tag

IO-Link Master

IO-Link Master  IO-Link Slave

IO-Link Slave  IO Module

IO Module  RFID System Communication Module

RFID System Communication Module

Handheld Barcode Scanner

Handheld Barcode Scanner  Fixed Barcode Scanner

Fixed Barcode Scanner