RF-HZ100L

Superisys

| Availability: | |

|---|---|

| Quantity: | |

RF-HZ100L is a high-performance, compact integrated UHF RFID Reader designed for industrial automation.

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | Discuss personally |

| Delivery Time | 5-8 Work Days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

Product Description

| Model | RF-HZ100L-R4 | RF-HZ100L-TP | RF-HZ100L-IOL |

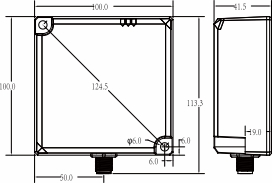

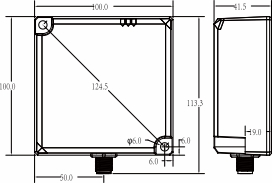

| Installation size |  | ||

| Wireless protocol | ISO 15963 | ||

| Working frequency | 13.56MHz | ||

| Output power | 27.5dBm | ||

| Communication interface | RS485 | Ethernet | IO Link |

| Communication protocol | MODBUS RTU | MODBUS TCP | IO Link V1.1 |

| Communication rate | 9600 ~ 115200bit/s | 10/100M adaptive | 230.4kbps |

| mains input | 9-30V DC | ||

| Average current | < 0.07A (24V DC) | ||

| Indicator light | 5* LED Light | ||

| Boundary dimension | 100*100*41.5mm | ||

| Fixture type | 2Pcs*M6 screw hole | ||

| Canning material | PC +ABS | ||

| Shell color | Black | ||

| Total weight | 350g | ||

| Operating temperature | -25 ~ 70℃ | ||

| Storage temperature | -40 ~ 85℃ | ||

| humidity | 5% ~ 95%RH(No condensation) | ||

| Waterproof and dustproof grade | IP65,EN60529 | ||

| Vibration resistance | 2mm(f=5…29.5Hz) ,EN60068-2-6 7gn(f=29.5…150Hz) ,EN60068-2-6 | ||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, over Class A/air discharge, 15KV, over class A | ||

| Certificate | FCC , CE | ||

| ROHS Standard | 2011/65/EU, 2015/863/EU | ||

RF-HZ100L is a high-performance, compact integrated UHF RFID Reader designed for industrial automation.

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | Discuss personally |

| Delivery Time | 5-8 Work Days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

Product Description

| Model | RF-HZ100L-R4 | RF-HZ100L-TP | RF-HZ100L-IOL |

| Installation size |  | ||

| Wireless protocol | ISO 15963 | ||

| Working frequency | 13.56MHz | ||

| Output power | 27.5dBm | ||

| Communication interface | RS485 | Ethernet | IO Link |

| Communication protocol | MODBUS RTU | MODBUS TCP | IO Link V1.1 |

| Communication rate | 9600 ~ 115200bit/s | 10/100M adaptive | 230.4kbps |

| mains input | 9-30V DC | ||

| Average current | < 0.07A (24V DC) | ||

| Indicator light | 5* LED Light | ||

| Boundary dimension | 100*100*41.5mm | ||

| Fixture type | 2Pcs*M6 screw hole | ||

| Canning material | PC +ABS | ||

| Shell color | Black | ||

| Total weight | 350g | ||

| Operating temperature | -25 ~ 70℃ | ||

| Storage temperature | -40 ~ 85℃ | ||

| humidity | 5% ~ 95%RH(No condensation) | ||

| Waterproof and dustproof grade | IP65,EN60529 | ||

| Vibration resistance | 2mm(f=5…29.5Hz) ,EN60068-2-6 7gn(f=29.5…150Hz) ,EN60068-2-6 | ||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, over Class A/air discharge, 15KV, over class A | ||

| Certificate | FCC , CE | ||

| ROHS Standard | 2011/65/EU, 2015/863/EU | ||

1. High-frequency communication and multi-protocol support

The operating frequency is 13.56MHz, supporting two international standard protocols, ISO15693 and ISO14443A.

2. Convenient secondary development support

Supports MODBUS RTU and MODBUS TCP protocols, which is convenient for users to carry out secondary development and system integration, and can easily access mainstream industrial automation systems.

3. High protection level and adaptability to harsh environments

The protection level reaches IP67, which can effectively resist harsh conditions such as oil, dust and moisture, ensuring the stable operation of the equipment in complex industrial environments.

4. Power supply protection and electromagnetic compatibility

The power supply has overcurrent, overvoltage protection and filtering functions, adapts to strong electromagnetic interference environments, and ensures the reliable operation of the equipment in complex electromagnetic fields.

1. Production line automation and process control

Tooling/fixture management: In scenarios such as automobile manufacturing and electronic assembly, the reader recognizes the HF tag on the tooling fixture and automatically switches production parameters (such as torque and program) to ensure process consistency.

Work-in-progress tracking: When parts or semi-finished products with HF tags pass through the production line, the reader records the processing status (such as completed spraying and testing) to achieve full process traceability.

Error-proofing system: Verify whether the material is correct at key workstations (such as scanning the label to match the model when assembling the engine) to avoid human errors.

2. Smart warehousing and logistics

Pallet/carton management: Metal or plastic pallets are embedded with anti-metal HF tags, and readers are used to scan in batches at the forklift channel or conveyor belt entrance to update inventory locations in real time.

AGV/robot guidance: AGV locates the path through HF tags embedded in the ground, or recognizes shelf tags to achieve automatic loading and unloading.

High-value material management: Labeling of assets such as precision instruments and molds, combined with fixed readers to monitor the status of in and out of the warehouse.

3. Equipment maintenance and life cycle management

Equipment inspection: HF tags are installed on industrial equipment (such as machine tools, pumps and valves), and maintenance personnel use handheld readers to scan and obtain maintenance records and maintenance plans.

Tool management: Shared tool cabinets use HF readers to identify borrowers and returners to prevent loss or overdue use.

4. Quality traceability and compliance

Product traceability: In the pharmaceutical and food industries, HF tags record production batches and process parameters, and readers write data in the packaging process to meet FDA/CE and other compliance requirements.

Recall management: When quality problems are found, the affected batches can be quickly located through tags to reduce the scope of recall.

5. Special industrial environment adaptation

Anti-metal/liquid interference: Industrial-grade HF readers use special antenna design, which can work stably near metal equipment or liquid containers (such as tanker inspection).

High temperature/dust environment: Readers with protection level of IP67 or above are suitable for harsh conditions such as foundry workshops and food processing.

1. High-frequency communication and multi-protocol support

The operating frequency is 13.56MHz, supporting two international standard protocols, ISO15693 and ISO14443A.

2. Convenient secondary development support

Supports MODBUS RTU and MODBUS TCP protocols, which is convenient for users to carry out secondary development and system integration, and can easily access mainstream industrial automation systems.

3. High protection level and adaptability to harsh environments

The protection level reaches IP67, which can effectively resist harsh conditions such as oil, dust and moisture, ensuring the stable operation of the equipment in complex industrial environments.

4. Power supply protection and electromagnetic compatibility

The power supply has overcurrent, overvoltage protection and filtering functions, adapts to strong electromagnetic interference environments, and ensures the reliable operation of the equipment in complex electromagnetic fields.

1. Production line automation and process control

Tooling/fixture management: In scenarios such as automobile manufacturing and electronic assembly, the reader recognizes the HF tag on the tooling fixture and automatically switches production parameters (such as torque and program) to ensure process consistency.

Work-in-progress tracking: When parts or semi-finished products with HF tags pass through the production line, the reader records the processing status (such as completed spraying and testing) to achieve full process traceability.

Error-proofing system: Verify whether the material is correct at key workstations (such as scanning the label to match the model when assembling the engine) to avoid human errors.

2. Smart warehousing and logistics

Pallet/carton management: Metal or plastic pallets are embedded with anti-metal HF tags, and readers are used to scan in batches at the forklift channel or conveyor belt entrance to update inventory locations in real time.

AGV/robot guidance: AGV locates the path through HF tags embedded in the ground, or recognizes shelf tags to achieve automatic loading and unloading.

High-value material management: Labeling of assets such as precision instruments and molds, combined with fixed readers to monitor the status of in and out of the warehouse.

3. Equipment maintenance and life cycle management

Equipment inspection: HF tags are installed on industrial equipment (such as machine tools, pumps and valves), and maintenance personnel use handheld readers to scan and obtain maintenance records and maintenance plans.

Tool management: Shared tool cabinets use HF readers to identify borrowers and returners to prevent loss or overdue use.

4. Quality traceability and compliance

Product traceability: In the pharmaceutical and food industries, HF tags record production batches and process parameters, and readers write data in the packaging process to meet FDA/CE and other compliance requirements.

Recall management: When quality problems are found, the affected batches can be quickly located through tags to reduce the scope of recall.

5. Special industrial environment adaptation

Anti-metal/liquid interference: Industrial-grade HF readers use special antenna design, which can work stably near metal equipment or liquid containers (such as tanker inspection).

High temperature/dust environment: Readers with protection level of IP67 or above are suitable for harsh conditions such as foundry workshops and food processing.