How UHF RFID Gateways Improve Inventory Accuracy and Real-time Tracking

Enhancing Operational Efficiency through UHF RFID Integration

The Role of Industrial RFID in Streamlining Warehouse Operations

Challenges in Implementing UHF RFID Gateways in Warehouse Settings

Future Trends in Warehouse Logistics and UHF RFID Technology

Warehouse logistics is an essential component of modern supply chains, and businesses are continually seeking innovative ways to enhance operational efficiency. One such technology making a significant impact is the use of UHF (Ultra High Frequency) RFID gateways. UHF RFID systems, which utilize electromagnetic waves for data transmission, are helping companies optimize their warehouse operations by providing real-time tracking and improving inventory accuracy.

In this article, we’ll explore how UHF RFID gateways contribute to optimizing warehouse logistics, focusing on their integration, benefits, and how they solve common logistical challenges. Additionally, we’ll discuss the specific role of Industrial RFID in warehouse settings and highlight the future of RFID technology in logistics.

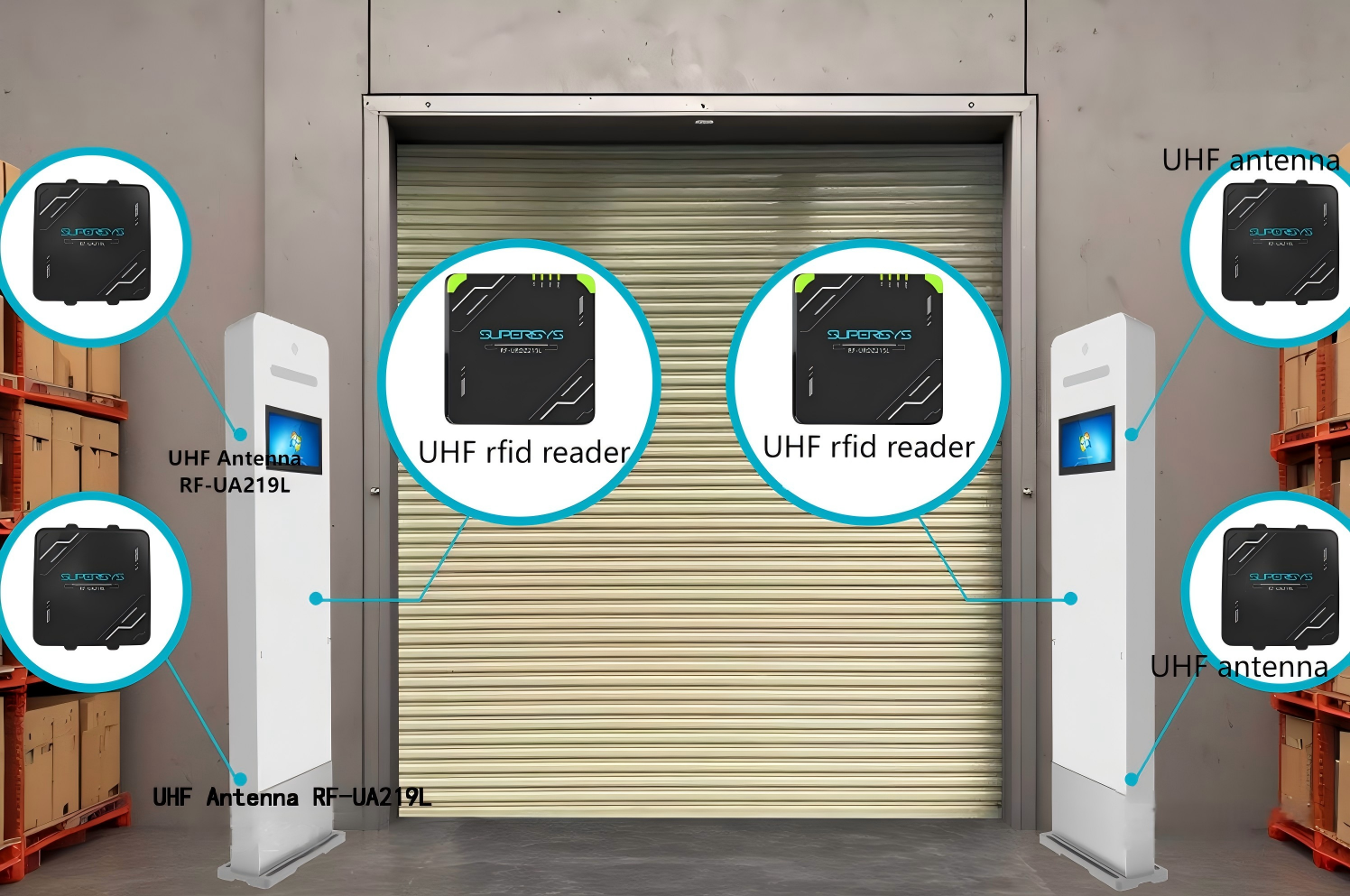

UHF RFID gateways act as the central points where RFID tags and readers work together to streamline the flow of information within warehouse logistics. These gateways are typically installed at critical entry and exit points of warehouses or along conveyor systems, enabling the tracking of tagged assets as they pass through.

An RFID gateway consists of a combination of UHF RFID readers, antennas, and software designed to capture data from RFID tags attached to items, pallets, or containers. As goods move through these designated zones, the gateway captures the RFID signals and sends them to the warehouse management system (WMS) or an enterprise resource planning (ERP) system for real-time tracking.

By using UHF RFID technology in warehouses, businesses gain precise control over their logistics operations, enabling them to monitor goods as they are stored, retrieved, or moved. UHF RFID gateways provide greater visibility, allowing for more effective resource allocation and minimizing the chance of human error.

One of the primary challenges in warehouse logistics is maintaining accurate inventory levels. Traditional manual methods of inventory management often result in human error, misplaced goods, and discrepancies between physical and recorded stock levels. UHF RFID gateways address this challenge by enabling real-time, automated tracking of goods throughout the warehouse.

With UHF RFID gateways, every item tagged with an RFID chip can be tracked in real-time, from the moment it enters the warehouse to its final destination. This real-time visibility not only improves inventory accuracy but also enhances stock management and replenishment processes. Automated data collection eliminates the need for time-consuming manual stocktaking, reducing labor costs and human error.

The use of UHF RFID gateways allows warehouse managers to see stock levels at any given moment, enabling them to make more informed decisions regarding replenishment and product movement. This results in reduced overstocking and stockouts, ensuring that inventory is available when needed and optimizing storage space.

Warehouse logistics can be complex, with multiple stages involved in receiving, storing, and dispatching goods. Integrating UHF RFID gateways into warehouse operations significantly enhances operational efficiency by automating key processes.

When goods pass through UHF RFID gateways, the system automatically captures data such as item identification, location, and movement. This automated data capture reduces the reliance on manual input, leading to faster processing and fewer errors. Automation speeds up activities such as stocktaking, receiving, order picking, and shipping, which can otherwise be time-intensive tasks.

UHF RFID gateways help identify bottlenecks in the warehouse, such as slow-moving stock or delays in processing certain goods. With this data, managers can optimize processes to ensure smoother operations. For example, the system might reveal that certain areas of the warehouse have higher congestion, prompting warehouse managers to reorganize storage or adjust staffing levels accordingly.

Industrial RFID, a more robust and specialized form of RFID technology, plays a crucial role in the broader context of warehouse logistics. Unlike general-purpose RFID, industrial-grade RFID systems are designed to withstand the harsh conditions often found in industrial environments, such as extreme temperatures, heavy machinery, and high humidity levels.

In warehouses that deal with bulky or sensitive goods, industrial RFID systems offer a higher level of durability and reliability compared to standard RFID solutions. UHF RFID gateways that integrate with industrial RFID systems can provide a more accurate and consistent tracking experience across various conditions, improving the efficiency of warehouse operations.

Industrial RFID solutions are essential for environments where conventional RFID tags might fail due to harsh conditions. These systems are resistant to physical wear and can perform reliably in extreme conditions. This is crucial in warehouses that deal with heavy equipment, outdoor storage, or refrigerated goods, ensuring that the tracking of assets remains accurate no matter the environment.

UHF RFID gateways offer a wide range of benefits for warehouse logistics, making them a valuable investment for businesses aiming to improve their supply chain operations. Below are some of the key advantages:

| Benefit | Description |

|---|---|

| Real-time Tracking | Provides up-to-the-minute visibility of goods as they move through the warehouse. |

| Increased Inventory Accuracy | Automated data collection reduces human errors and ensures inventory is accurately tracked. |

| Faster Operations | Speeds up stocktaking, receiving, and order picking by automating manual processes. |

| Space Optimization | Helps optimize storage space by providing insights into item movements and warehouse layouts. |

| Improved Customer Service | Real-time visibility leads to faster and more accurate order fulfillment, improving customer satisfaction. |

By integrating UHF RFID gateways, warehouses can significantly reduce operational costs while improving efficiency, accuracy, and visibility across their supply chain.

While UHF RFID gateways offer numerous benefits, their implementation can come with challenges. Some common obstacles include:

The cost of implementing RFID technology, including purchasing RFID tags, readers, gateways, and upgrading existing systems, can be significant. However, many businesses find that the long-term cost savings and efficiency improvements justify the initial expense.

The installation of UHF RFID gateways often requires a significant upgrade in infrastructure, such as the addition of antennas, readers, and data integration systems. This can be challenging for businesses with limited resources or outdated technology.

Older warehouse management systems (WMS) may not always be compatible with modern RFID technology. Ensuring seamless integration between RFID systems and existing IT infrastructure is essential for a successful deployment.

As warehouse logistics continue to evolve, UHF RFID technology is expected to play an even more significant role. Emerging trends such as the adoption of the Internet of Things (IoT) and artificial intelligence (AI) are likely to further enhance the capabilities of RFID systems.

The integration of IoT with UHF RFID systems will allow for more intelligent and interconnected warehouse environments. IoT sensors can work alongside RFID tags to provide even more detailed information about the condition of goods, such as temperature, humidity, or shock, allowing warehouses to make data-driven decisions in real-time.

Artificial intelligence can take data from RFID gateways and use machine learning algorithms to predict trends and optimize warehouse processes. AI could help identify inefficiencies or areas for improvement, further enhancing the effectiveness of UHF RFID in warehouse logistics.

UHF RFID gateways have proven to be a game-changer in optimizing warehouse logistics. By improving inventory accuracy, enhancing operational efficiency, and providing real-time visibility, RFID technology addresses many of the challenges warehouses face today. As industrial RFID continues to evolve, we can expect even more advanced solutions to emerge, streamlining logistics processes and setting new standards for supply chain management.

1. What is the primary function of UHF RFID gateways in warehouse logistics?

UHF RFID gateways capture signals from RFID tags attached to items or pallets, providing real-time tracking and data collection. This enhances inventory accuracy and operational efficiency within the warehouse.

2. Can UHF RFID work in harsh warehouse environments?

Yes, UHF RFID systems, particularly industrial-grade RFID, are designed to withstand harsh conditions like extreme temperatures, moisture, and physical wear, making them ideal for warehouses with demanding environments.

3. What are the main benefits of using UHF RFID in warehouse logistics?

The main benefits include increased inventory accuracy, real-time tracking, operational speed, and improved customer satisfaction due to more accurate order fulfillment and better warehouse management.

4. Are there any challenges in implementing UHF RFID gateways?

Challenges include high initial costs, infrastructure upgrades, and potential compatibility issues with existing systems. However, these challenges are often outweighed by the long-term operational benefits.

5. How does UHF RFID improve inventory accuracy?

By automating data capture and real-time tracking, UHF RFID reduces the reliance on manual processes, which can be prone to errors, ensuring more accurate and up-to-date inventory data.