CR-HC811X-12RA

Superisys

| Availability: | |

|---|---|

| Quantity: | |

• CMOS upgrade, supports 230W, 500W

• Quad-core parallel computing, ultra-high efficiency decoding

• Dynamic code reading, dynamic reading, the fastest supports 6M/S

• Support multiple groups of 10, meet complex input and output requirements

• Multiple indicator lights, intuitive display ofcode reading status

• Multiple lenses optional, support liquid lens

• IP65 protection level

| Minimum Order Quantity | 1 |

| Delivery Time | 8 Work Days |

| Stock | In Stock |

| Payment Terms | T/T, Western Union |

| Model | CR-HC811X-06RA | CR-HC811X-12RA | CR-HC812X-06RA | CR-HC812X-12RA | CR-HC815X-06RA | CR-HC815X-12RA |

| Sensor Type | Global shutter CMOS image sensor | |||||

| Resolution | 1280*1080 | 1920*1200 | 2592*1944 | |||

| colour | Black&White | |||||

| Frame rate | 120fps | 108fps | 45fps | |||

| Host processor | 4x1.6GHz main frequency Cortex-A53 | |||||

| Machine learning vision processor | 23TOPS NPU | |||||

| Light source | Red and white optional, 32 high-lighted leds | |||||

| Input voltage | 5V-24V DC ±10% | |||||

| Power | <5W | |||||

| Import | 2 optical coupling isolated inputs, support NPN, PNP access mode | |||||

| Output | 3 optical coupling isolated output, support NPN, PNP, switch control mode | |||||

| Serial port | RS232C, RS485, support no protocol, ModBus RTU protocol | |||||

| Ethernet | 100, Gigabit Ethernet (optional, support TCP/IP, ModbusTCP, EthernetIP, Profinet, Melsec and other protoc | |||||

| 2D | DataMatrix,QR code, MicroQR, Vericode, Maxcode,PDF417,etc | |||||

| 1D | Code 128, Code 39, Code 93, Code 11 , Interleaved 2 of 5 , Codabar, GS1 DataBar, UPC, EAN,etc. | |||||

| Min. Resolution | 0.08mm | 0.05mm | 0.08mm | 0.05mm | 0.06mm | 0.04mm |

| Field Angle | Horizontal 31° Vertical :26° | Horizontal :16° Vertical :13° | Horizontal :49° Vertical :32° | Horizontal :27° Vertical :17° | Horizontal 49° Vertical :38° | Horizontal :26° Vertical :20° |

| Field of view | 6mm | 12mm | 6.21mm | 12mm | 6.21mm | 12mm |

| Distance | 60mm-600mm | 75mm-600mm | 60-600mm | 75mm-600mm | 60mm-600mm | 75mm-600mm |

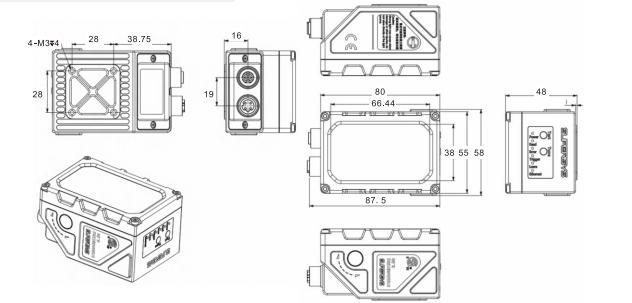

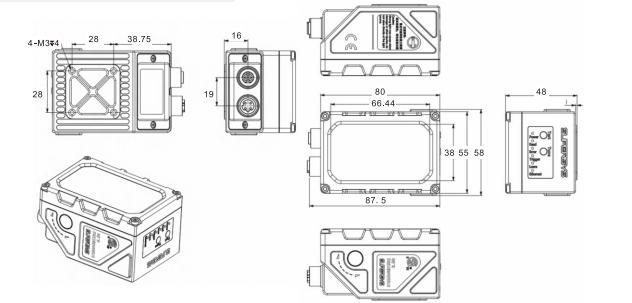

| Weight | About 240g | |||||

| Operating temperature | -10°C~+50°C | |||||

| Storage temperature | -20°C~+70°C | |||||

| Humidity | 5% to 95% no condensation | |||||

| Electrostatic protection | +8KV(direct discharge) | |||||

| Level of protection | IP65 | |||||

• CMOS upgrade, supports 230W, 500W

• Quad-core parallel computing, ultra-high efficiency decoding

• Dynamic code reading, dynamic reading, the fastest supports 6M/S

• Support multiple groups of 10, meet complex input and output requirements

• Multiple indicator lights, intuitive display ofcode reading status

• Multiple lenses optional, support liquid lens

• IP65 protection level

| Minimum Order Quantity | 1 |

| Delivery Time | 8 Work Days |

| Stock | In Stock |

| Payment Terms | T/T, Western Union |

| Model | CR-HC811X-06RA | CR-HC811X-12RA | CR-HC812X-06RA | CR-HC812X-12RA | CR-HC815X-06RA | CR-HC815X-12RA |

| Sensor Type | Global shutter CMOS image sensor | |||||

| Resolution | 1280*1080 | 1920*1200 | 2592*1944 | |||

| colour | Black&White | |||||

| Frame rate | 120fps | 108fps | 45fps | |||

| Host processor | 4x1.6GHz main frequency Cortex-A53 | |||||

| Machine learning vision processor | 23TOPS NPU | |||||

| Light source | Red and white optional, 32 high-lighted leds | |||||

| Input voltage | 5V-24V DC ±10% | |||||

| Power | <5W | |||||

| Import | 2 optical coupling isolated inputs, support NPN, PNP access mode | |||||

| Output | 3 optical coupling isolated output, support NPN, PNP, switch control mode | |||||

| Serial port | RS232C, RS485, support no protocol, ModBus RTU protocol | |||||

| Ethernet | 100, Gigabit Ethernet (optional, support TCP/IP, ModbusTCP, EthernetIP, Profinet, Melsec and other protoc | |||||

| 2D | DataMatrix,QR code, MicroQR, Vericode, Maxcode,PDF417,etc | |||||

| 1D | Code 128, Code 39, Code 93, Code 11 , Interleaved 2 of 5 , Codabar, GS1 DataBar, UPC, EAN,etc. | |||||

| Min. Resolution | 0.08mm | 0.05mm | 0.08mm | 0.05mm | 0.06mm | 0.04mm |

| Field Angle | Horizontal 31° Vertical :26° | Horizontal :16° Vertical :13° | Horizontal :49° Vertical :32° | Horizontal :27° Vertical :17° | Horizontal 49° Vertical :38° | Horizontal :26° Vertical :20° |

| Field of view | 6mm | 12mm | 6.21mm | 12mm | 6.21mm | 12mm |

| Distance | 60mm-600mm | 75mm-600mm | 60-600mm | 75mm-600mm | 60mm-600mm | 75mm-600mm |

| Weight | About 240g | |||||

| Operating temperature | -10°C~+50°C | |||||

| Storage temperature | -20°C~+70°C | |||||

| Humidity | 5% to 95% no condensation | |||||

| Electrostatic protection | +8KV(direct discharge) | |||||

| Level of protection | IP65 | |||||

Automotive parts traceability

Read the QR code of parts on the welding/assembly line, bind production data to the MES system, and achieve full life cycle tracking.

Express logistics sorting

Integrated in the sorting machine, high-speed identification of the parcel surface single barcode, improve sorting accuracy and throughput.

Drug packaging supervision

Scan the QR code of the drug packaging to verify the batch information to ensure compliance and anti-counterfeiting traceability.

Food production traceability

Read the laser marking code on the metal can body and record key data such as production time and production line number.

Warehouse inventory management

Fixed installation on the shelf channel, automatically scan the pallet barcode, and update the inventory status in real time.

Automotive parts traceability

Read the QR code of parts on the welding/assembly line, bind production data to the MES system, and achieve full life cycle tracking.

Express logistics sorting

Integrated in the sorting machine, high-speed identification of the parcel surface single barcode, improve sorting accuracy and throughput.

Drug packaging supervision

Scan the QR code of the drug packaging to verify the batch information to ensure compliance and anti-counterfeiting traceability.

Food production traceability

Read the laser marking code on the metal can body and record key data such as production time and production line number.

Warehouse inventory management

Fixed installation on the shelf channel, automatically scan the pallet barcode, and update the inventory status in real time.

FAQ

Q1: Can the Barcode Reader scan normally in a strong light environment?

A: Yes. The device has built-in anti-reflection algorithms and adaptive LED fill light, which can cope with direct sunlight or high-intensity lighting environments.

Q2: Does it support reading barcodes on curved surfaces?

A: Yes. Through dynamic focal length adjustment, barcodes on cylindrical containers (such as beverage bottles) or curved metal parts can be read.

Q3: How to clean the lens and protective cover?

A: The IP67 design can be wiped directly with a wet cloth to avoid the use of corrosive solvents. Regular monthly maintenance is recommended.

Q4: Can it be connected to the existing WMS/MES system?

A: Yes. Provide standard communication protocols (TCP/IP, PROFINET) and API interfaces for quick connection to enterprise management systems.

Q5: Does the device installation require professional debugging?

A: Plug-and-play design, providing autofocus and parameter preset functions, ordinary engineers can complete deployment within 15 minutes.

FAQ

Q1: Can the Barcode Reader scan normally in a strong light environment?

A: Yes. The device has built-in anti-reflection algorithms and adaptive LED fill light, which can cope with direct sunlight or high-intensity lighting environments.

Q2: Does it support reading barcodes on curved surfaces?

A: Yes. Through dynamic focal length adjustment, barcodes on cylindrical containers (such as beverage bottles) or curved metal parts can be read.

Q3: How to clean the lens and protective cover?

A: The IP67 design can be wiped directly with a wet cloth to avoid the use of corrosive solvents. Regular monthly maintenance is recommended.

Q4: Can it be connected to the existing WMS/MES system?

A: Yes. Provide standard communication protocols (TCP/IP, PROFINET) and API interfaces for quick connection to enterprise management systems.

Q5: Does the device installation require professional debugging?

A: Plug-and-play design, providing autofocus and parameter preset functions, ordinary engineers can complete deployment within 15 minutes.