RF-URDZ215L-EU-PN/EIP/ECT

Superisys

| Availability: | |

|---|---|

| Quantity: | |

Built-in antenna, compact in size, easy to install, andconvenient to use.

Supports both active and passive reading modes, effectively saving reading energy consumption.

Excellent anti-collision algorithm, with the highest tagrecognition rate reaching 120pcs/s.

Global Gen2 platform, adaptable to RFID application needs in different countries and regions.

RF power output range is 10~26dBm, adjustable via software.

Superior reception sensitivity, reaching up to 5-30dBm.

Support Multi-tag reading, fast speed.

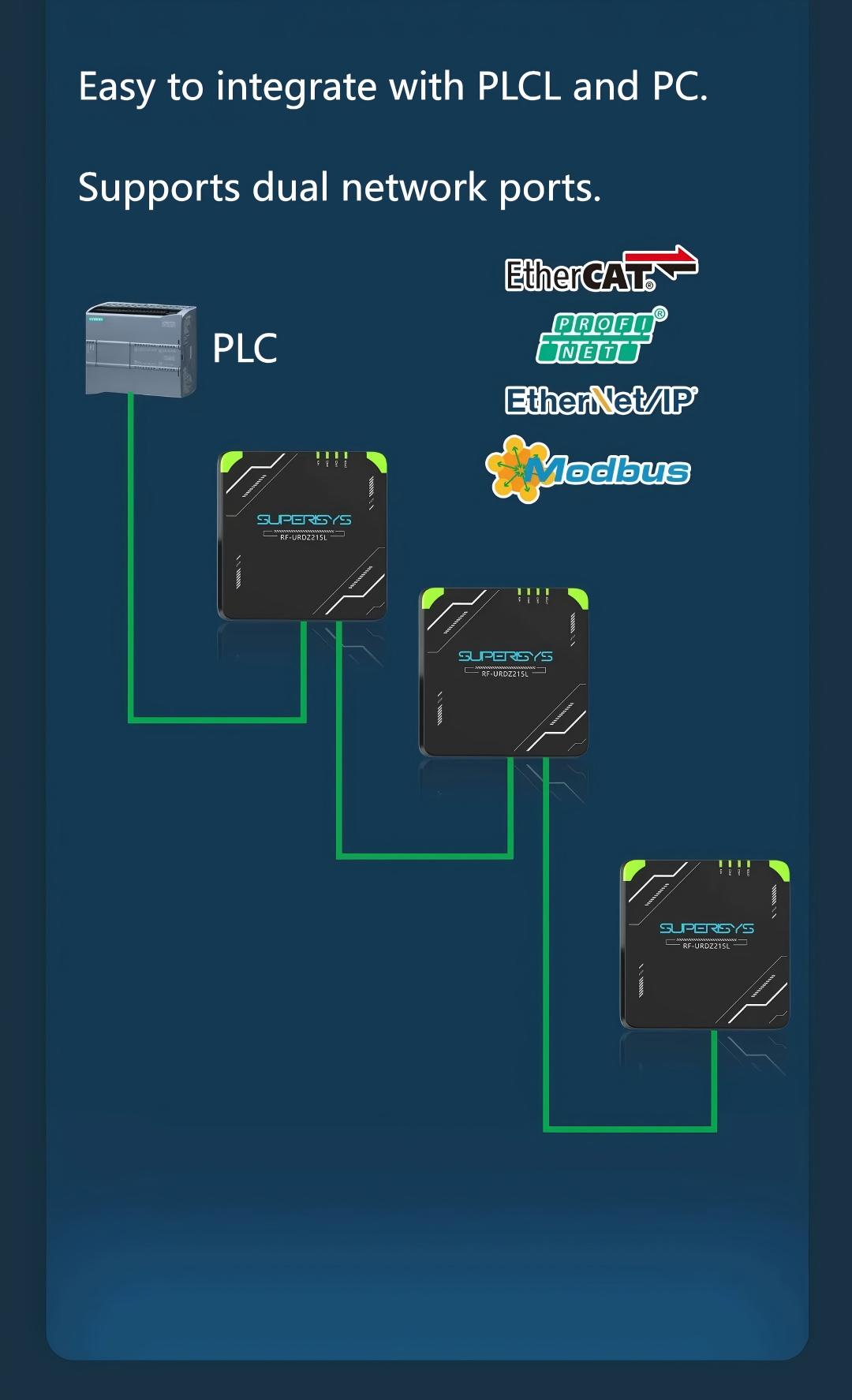

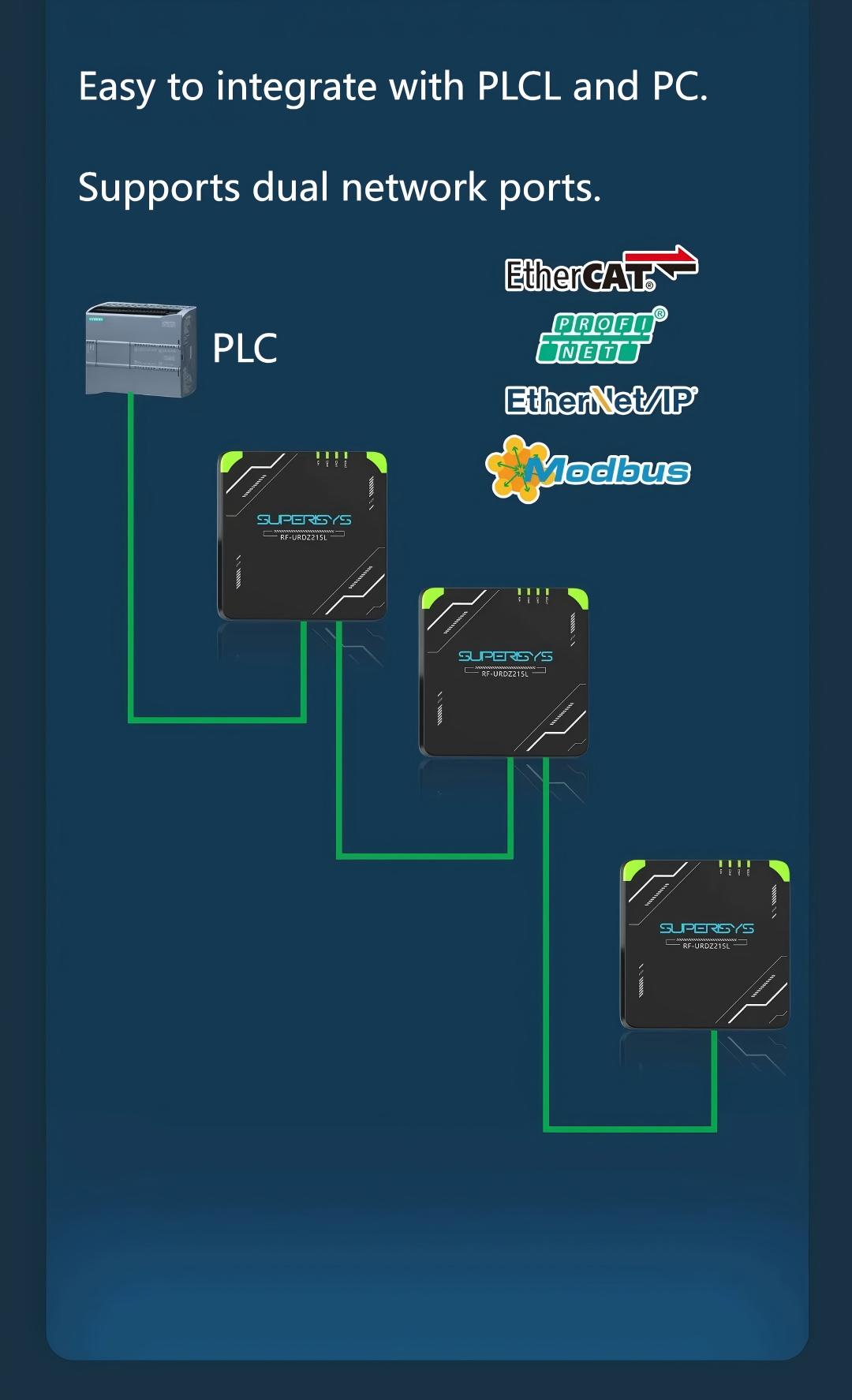

Support Profinet, Ethernet/IP EtherCAT , integrates seamlessly with PLC and SCADA systems to enable real-time command interaction.

Technical Parameters

| Model | RF-URDZ215L-PN | RF-URDZ215L-EIP | RF-URDZ215L-ECT |

| Wireless protocol | ISO 18000-6c(Class1 Gen2) | ||

| Working frequency | CN:920-925MHz(SRRC) | ||

| Output power | 5-30dBm adjust(Stepping 1dbm) | ||

| Communication interface | RS485*1 Ethernet*2 | ||

| Communication protocol | ProfiNet | Ethernet/IP | EtherCAT |

| Communication rate | 10/100M adaptive | ||

| mains input | 9-30V DC | ||

| Average current | < 0.5A (24V DC) | ||

| Indicator light | 6* LED Light | ||

| Boundary dimension | 215*215*58mm | ||

| Fixture type | 4Pcs*M6 screw hole | ||

| Canning material | Base: Aluminum Alloy, Top: PC +ABS | ||

| Shell color | Black | ||

| Operating temperature | -25 ~ 70℃ | ||

| Storage temperature | -40 ~ 85℃ | ||

| humidity | 5% ~ 95%RH(No condensation) | ||

| Waterproof and dustproof grade | IP65,EN60529 | ||

| Vibration resistance | 2mm(f=5…29.5Hz) ,EN60068-2-6 7gn(f=29.5…150Hz) ,EN60068-2-6 | ||

| Electrostatic discharge immunity ESD | IEC610000-4-2 | ||

| Certificate | FCC , CE,ROHS | ||

Built-in antenna, compact in size, easy to install, andconvenient to use.

Supports both active and passive reading modes, effectively saving reading energy consumption.

Excellent anti-collision algorithm, with the highest tagrecognition rate reaching 120pcs/s.

Global Gen2 platform, adaptable to RFID application needs in different countries and regions.

RF power output range is 10~26dBm, adjustable via software.

Superior reception sensitivity, reaching up to 5-30dBm.

Support Multi-tag reading, fast speed.

Support Profinet, Ethernet/IP EtherCAT , integrates seamlessly with PLC and SCADA systems to enable real-time command interaction.

Technical Parameters

| Model | RF-URDZ215L-PN | RF-URDZ215L-EIP | RF-URDZ215L-ECT |

| Wireless protocol | ISO 18000-6c(Class1 Gen2) | ||

| Working frequency | CN:920-925MHz(SRRC) | ||

| Output power | 5-30dBm adjust(Stepping 1dbm) | ||

| Communication interface | RS485*1 Ethernet*2 | ||

| Communication protocol | ProfiNet | Ethernet/IP | EtherCAT |

| Communication rate | 10/100M adaptive | ||

| mains input | 9-30V DC | ||

| Average current | < 0.5A (24V DC) | ||

| Indicator light | 6* LED Light | ||

| Boundary dimension | 215*215*58mm | ||

| Fixture type | 4Pcs*M6 screw hole | ||

| Canning material | Base: Aluminum Alloy, Top: PC +ABS | ||

| Shell color | Black | ||

| Operating temperature | -25 ~ 70℃ | ||

| Storage temperature | -40 ~ 85℃ | ||

| humidity | 5% ~ 95%RH(No condensation) | ||

| Waterproof and dustproof grade | IP65,EN60529 | ||

| Vibration resistance | 2mm(f=5…29.5Hz) ,EN60068-2-6 7gn(f=29.5…150Hz) ,EN60068-2-6 | ||

| Electrostatic discharge immunity ESD | IEC610000-4-2 | ||

| Certificate | FCC , CE,ROHS | ||

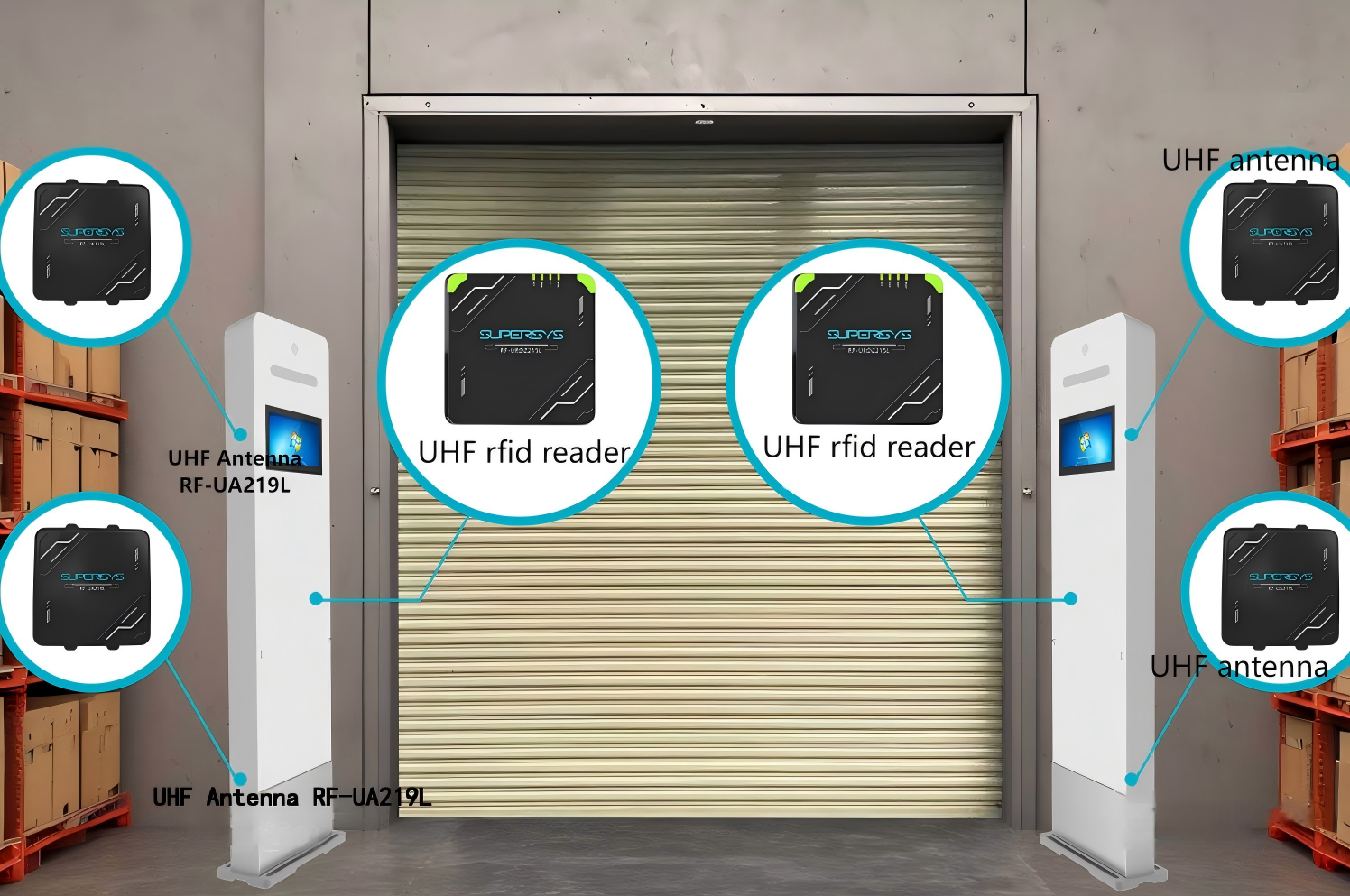

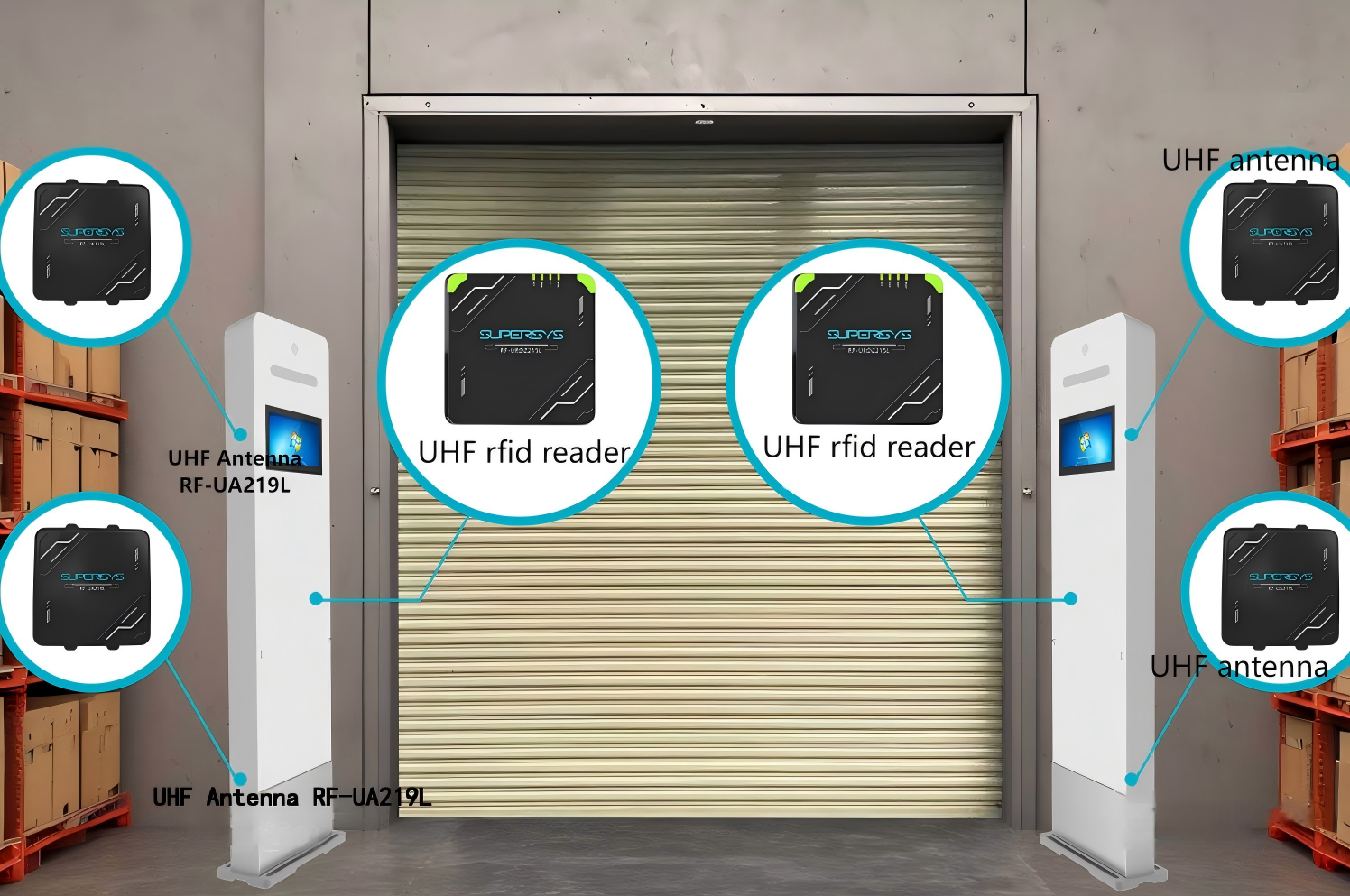

Inbound and Outbound Management: Installed at the warehouse gate or above a conveyor belt, this reader automatically records and verifies UHF-tagged goods (full pallets, full boxes) in batches, eliminating manual intervention and achieving near-100% accuracy and exceptional efficiency.

Inventory Counting: Workers can quickly complete large-scale inventory counts by using a handheld reader (assuming a handheld form factor is available) or by driving a forklift equipped with the reader between shelves.

Production Line Material Management: Installed above a production line workstation, it automatically identifies product pallets or carriers in motion, triggering corresponding assembly instructions or recording production information, enabling lean production and full-process traceability.

In the automotive manufacturing industry, one vehicle, one tag.

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | Discuss personally |

| Delivery Time | 5-8 Work Days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

Inbound and Outbound Management: Installed at the warehouse gate or above a conveyor belt, this reader automatically records and verifies UHF-tagged goods (full pallets, full boxes) in batches, eliminating manual intervention and achieving near-100% accuracy and exceptional efficiency.

Inventory Counting: Workers can quickly complete large-scale inventory counts by using a handheld reader (assuming a handheld form factor is available) or by driving a forklift equipped with the reader between shelves.

Production Line Material Management: Installed above a production line workstation, it automatically identifies product pallets or carriers in motion, triggering corresponding assembly instructions or recording production information, enabling lean production and full-process traceability.

In the automotive manufacturing industry, one vehicle, one tag.

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | Discuss personally |

| Delivery Time | 5-8 Work Days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |