IACM-IOLM4A-ECT/PN/EIP

Superisys

| Availability: | |

|---|---|

| Quantity: | |

IO-Link Master

Function: It is the core controller of the IO-Link network. It is responsible for high-speed communication with upper-level control systems (such as PLCs) (via Profinet, EtherNet/IP, etc.), and manages bidirectional point-to-point communication with multiple lower-level IO-Link devices.

Functions: Powers IO-Link devices, configures parameters, collects process data (such as sensor values), and receives device status and diagnostic information.

Number of Ports: 4 ports

This means that one master module can connect to up to 4 IO-Link devices simultaneously.

This multi-port design is ideal for centrally connecting multiple sensors and actuators in densely populated workstations (such as assembly stations and testing stations).

Class A: Only supports three communication rates: COM1 (4.8 kbps), COM2 (38.4 kbps), and COM3 (230.4 kbps). It does not support the fastest COM3 (230.4 kbps) rate.

Simplified Wiring: Transforms traditional point-to-point hard wiring (each sensor requiring a multi-core cable back to the PLC) into a star connection using a single standard 3- or 4-wire M12 cable, saving up to 90% of cabling and wiring work.

Digitalization and Intelligence: Not only can it transmit switch signals (0/1), but it can also transmit rich process data (such as analog values, text information) and parameter data.

Powerful Diagnostic Functions: Real-time monitoring of equipment status (short circuit, open circuit, overload, contamination, overheating, etc.) enables predictive maintenance.

Seamless Replacement and Parameterization: When replacing equipment, the master station can automatically download stored parameters to the new equipment, achieving "plug and play" and greatly reducing downtime.

| Model | IACM-IOLM4A-ECT | IACM-IOLM4A-PN | IACM-IOLM4A-EIP |

| Communication protocol |  |  |  |

Shell Material | Aluminum Alloy | ||

| Color | Silver | ||

| Product description | IO-LINK master module | ||

| 4 Class A port | |||

| IP67 protection class | |||

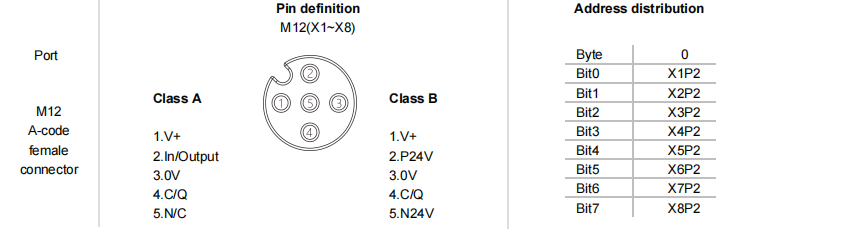

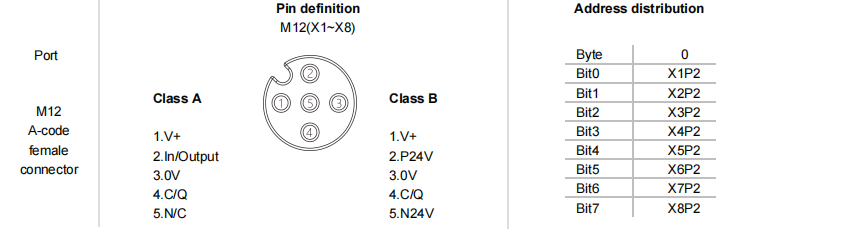

| I/O connection mode | M12, 5pin hole holder, A code | ||

| IO-Link master parameters | |||

| Number of master stations | The maximum configurable 4 ports | ||

| Master connection mode | M12, 5-core, A-code, female head | ||

| lO-link version | V1.1.2 | ||

| Communication rate | COM1: 4.8KBps | ||

| COM2: 38.4KBps | |||

| COM3: 230.4KBps | |||

| The port voltage is L+ | type.24VDC(via US) | ||

| The port current is L+ | 2A(via US) | ||

| Class A | 4port ,X1.….X4 | ||

| Master-Slave communication distance | ≤20m | ||

| Master-master communication distance | ≤100m | ||

| Digital input and output parameters | |||

| Number of inputs | 4 way, adaptive | ||

| Input port location | X1…X4 | ||

| Polarity of input | PNP | ||

| Signal "0" voltage | -0.3…5VDC | ||

| Signal "1" voltage | 12…30VDC | ||

| incoming current | type.5mA(via US) | ||

| Number of outputs | 4 way, adaptive | ||

| Output port location | X1…X4 | ||

| Polarity of input | PNP | ||

| current output | Single channel 2A(via UA) | ||

| Port protection | Power short circuit protection, power supply port overload protection | ||

| Pin Definition | |||

| |||

IO-Link Master

Function: It is the core controller of the IO-Link network. It is responsible for high-speed communication with upper-level control systems (such as PLCs) (via Profinet, EtherNet/IP, etc.), and manages bidirectional point-to-point communication with multiple lower-level IO-Link devices.

Functions: Powers IO-Link devices, configures parameters, collects process data (such as sensor values), and receives device status and diagnostic information.

Number of Ports: 4 ports

This means that one master module can connect to up to 4 IO-Link devices simultaneously.

This multi-port design is ideal for centrally connecting multiple sensors and actuators in densely populated workstations (such as assembly stations and testing stations).

Class A: Only supports three communication rates: COM1 (4.8 kbps), COM2 (38.4 kbps), and COM3 (230.4 kbps). It does not support the fastest COM3 (230.4 kbps) rate.

Simplified Wiring: Transforms traditional point-to-point hard wiring (each sensor requiring a multi-core cable back to the PLC) into a star connection using a single standard 3- or 4-wire M12 cable, saving up to 90% of cabling and wiring work.

Digitalization and Intelligence: Not only can it transmit switch signals (0/1), but it can also transmit rich process data (such as analog values, text information) and parameter data.

Powerful Diagnostic Functions: Real-time monitoring of equipment status (short circuit, open circuit, overload, contamination, overheating, etc.) enables predictive maintenance.

Seamless Replacement and Parameterization: When replacing equipment, the master station can automatically download stored parameters to the new equipment, achieving "plug and play" and greatly reducing downtime.

| Model | IACM-IOLM4A-ECT | IACM-IOLM4A-PN | IACM-IOLM4A-EIP |

| Communication protocol |  |  |  |

Shell Material | Aluminum Alloy | ||

| Color | Silver | ||

| Product description | IO-LINK master module | ||

| 4 Class A port | |||

| IP67 protection class | |||

| I/O connection mode | M12, 5pin hole holder, A code | ||

| IO-Link master parameters | |||

| Number of master stations | The maximum configurable 4 ports | ||

| Master connection mode | M12, 5-core, A-code, female head | ||

| lO-link version | V1.1.2 | ||

| Communication rate | COM1: 4.8KBps | ||

| COM2: 38.4KBps | |||

| COM3: 230.4KBps | |||

| The port voltage is L+ | type.24VDC(via US) | ||

| The port current is L+ | 2A(via US) | ||

| Class A | 4port ,X1.….X4 | ||

| Master-Slave communication distance | ≤20m | ||

| Master-master communication distance | ≤100m | ||

| Digital input and output parameters | |||

| Number of inputs | 4 way, adaptive | ||

| Input port location | X1…X4 | ||

| Polarity of input | PNP | ||

| Signal "0" voltage | -0.3…5VDC | ||

| Signal "1" voltage | 12…30VDC | ||

| incoming current | type.5mA(via US) | ||

| Number of outputs | 4 way, adaptive | ||

| Output port location | X1…X4 | ||

| Polarity of input | PNP | ||

| current output | Single channel 2A(via UA) | ||

| Port protection | Power short circuit protection, power supply port overload protection | ||

| Pin Definition | |||

| |||

Automobile welding production line

Synchronously control welding robots, fixtures and visual inspection systems, and upload welding quality data to MES in real time.

3C electronic assembly

Links SMT machines, screw machines and AOI inspection equipment to achieve high-precision component assembly and defect detection.

Food and beverage filling

Integrates flow meters, temperature control sensors and filling valves to accurately control filling volume and temperature through IO-LINK.

Photovoltaic panel production

Monitor the pressure and temperature parameters of the laminator, adjust process parameters in real time, and improve the yield rate.

Smart warehousing logistics

Connect sorting robots, AGVs and RFID readers to optimize warehousing efficiency.

| Minimum Order Quantity | one |

| Delivery Time | 1-2 work days |

| Stock | In Stock |

| Description | 8-port series, IOLINK master station |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

Automobile welding production line

Synchronously control welding robots, fixtures and visual inspection systems, and upload welding quality data to MES in real time.

3C electronic assembly

Links SMT machines, screw machines and AOI inspection equipment to achieve high-precision component assembly and defect detection.

Food and beverage filling

Integrates flow meters, temperature control sensors and filling valves to accurately control filling volume and temperature through IO-LINK.

Photovoltaic panel production

Monitor the pressure and temperature parameters of the laminator, adjust process parameters in real time, and improve the yield rate.

Smart warehousing logistics

Connect sorting robots, AGVs and RFID readers to optimize warehousing efficiency.

| Minimum Order Quantity | one |

| Delivery Time | 1-2 work days |

| Stock | In Stock |

| Description | 8-port series, IOLINK master station |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

FAQ

Q1: Does the IO-LINK master module require a dedicated gateway?

A: No additional gateway is required. The module directly integrates the EtherCAT/Profinet protocol and can be directly connected to the PLC master.

Q2: Can the 8 ports support devices with different protocols at the same time?

A: Yes. Each IO-LINK port works independently and can be mixed with sensors, actuators and other devices.

Q3: Is the protection level of the module suitable for oily environments?

A: IP67 protection design, resistant to oil, dust and water mist, but long-term immersion or high-pressure washing should be avoided.

Q4: Does it support third-party IO-LINK devices?

A: Fully compatible with IO-LINK V1.1 standard devices, including IFM, SICK and other brand sensors.

Q5: How to achieve multi-module cascade expansion?

A: Through the EtherCAT daisy chain topology, up to 32 modules can be cascaded and 256 IO-LINK nodes can be managed.

FAQ

Q1: Does the IO-LINK master module require a dedicated gateway?

A: No additional gateway is required. The module directly integrates the EtherCAT/Profinet protocol and can be directly connected to the PLC master.

Q2: Can the 8 ports support devices with different protocols at the same time?

A: Yes. Each IO-LINK port works independently and can be mixed with sensors, actuators and other devices.

Q3: Is the protection level of the module suitable for oily environments?

A: IP67 protection design, resistant to oil, dust and water mist, but long-term immersion or high-pressure washing should be avoided.

Q4: Does it support third-party IO-LINK devices?

A: Fully compatible with IO-LINK V1.1 standard devices, including IFM, SICK and other brand sensors.

Q5: How to achieve multi-module cascade expansion?

A: Through the EtherCAT daisy chain topology, up to 32 modules can be cascaded and 256 IO-LINK nodes can be managed.