IACM-IOLM8A-ECT/PN/EIP

Superisys

| Availability: | |

|---|---|

| Quantity: | |

Superisys single master station can connect to up to 8 IO-Link devices.

Application Implications:

Higher Integration: In areas with a high concentration of sensors/actuators (such as large assembly units, complex inspection stations, and multi-axis machining centers), a single device can cover the entire workstation, significantly reducing network nodes and IP address usage.

Lower Single-Point Cost: Compared to using two 4-port master stations, an 8-port master station typically has a lower total cost of ownership in terms of hardware, installation, cabling, and management.

Simplified System Architecture: Achieve equivalent or enhanced control functions with fewer physical modules, simplifying cabinet or field installation.

Applicable Equipment: Over 90% of field devices, such as:

All types of discrete sensors (photoelectric, proximity, ultrasonic)

Common actuators (valve islands, indicator lights, simple cylinder sensors)

Most analog input devices (pressure, temperature transmitters)

RFID readers, display units, etc. with basic diagnostic functions.

| Model | IACM-IOLM8A-ECT | IACM-IOLM8A-PN | IACM-IOLM8A-EIP |

| Communication protocol |  |  |  |

Shell Material | Aluminum Alloy | ||

| Color | Silver | ||

| Product description | IO-LINK master module | ||

| 8 Class A port | |||

| IP67 protection class | |||

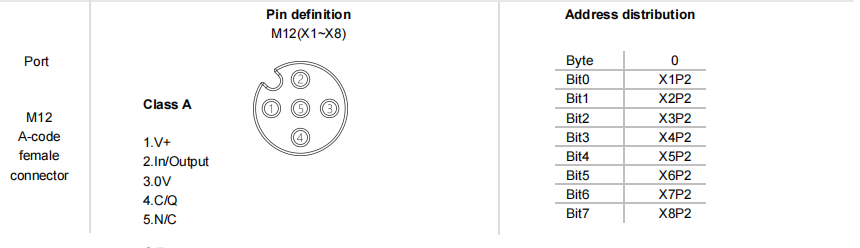

| I/O connection mode | M12, 5pin hole holder, A code | ||

| IO-Link master parameters | |||

| Number of master stations | The maximum configurable 8 ports | ||

| Master connection mode | M12, 5-core, A-code, female head | ||

| lO-link version | V1.1.2 | ||

| Communication rate | COM1:4.8KBps | ||

| COM2;38.4KBps | |||

| COM3:230.4KBps | |||

| The port voltage is L+ | type.24VDC(via US) | ||

| The port current is L+ | 2A(via US) | ||

| ClassB auxiliary voltage | - | ||

| ClassB auxiliary voltage | - | ||

| Class A | 8port ,X1.….X8 | ||

| Class B | - | ||

| Master-slave communication distance | ≤20 meters | ||

| Master-master communication distance | ≤100meters | ||

| Digital input and output parameters | |||

| Number of inputs | 8 way, adaptive | ||

| Input port location | X1…X8 | ||

| Polarity of input | PNP | ||

| Signal "0" voltage | -0.3…5VDC | ||

| Signal "1" voltage | 12…30VDC | ||

| incoming current | type.5mA(via US) | ||

| Number of outputs | 8 way, adaptive | ||

| Output port location | X1…X8 | ||

| Polarity of input | PNP | ||

| current output | Single channel 2A(via UA) | ||

| Port protection | Power short circuit protection, power supply port overload protection | ||

| Pin definition | |||

| |||

Superisys single master station can connect to up to 8 IO-Link devices.

Application Implications:

Higher Integration: In areas with a high concentration of sensors/actuators (such as large assembly units, complex inspection stations, and multi-axis machining centers), a single device can cover the entire workstation, significantly reducing network nodes and IP address usage.

Lower Single-Point Cost: Compared to using two 4-port master stations, an 8-port master station typically has a lower total cost of ownership in terms of hardware, installation, cabling, and management.

Simplified System Architecture: Achieve equivalent or enhanced control functions with fewer physical modules, simplifying cabinet or field installation.

Applicable Equipment: Over 90% of field devices, such as:

All types of discrete sensors (photoelectric, proximity, ultrasonic)

Common actuators (valve islands, indicator lights, simple cylinder sensors)

Most analog input devices (pressure, temperature transmitters)

RFID readers, display units, etc. with basic diagnostic functions.

| Model | IACM-IOLM8A-ECT | IACM-IOLM8A-PN | IACM-IOLM8A-EIP |

| Communication protocol |  |  |  |

Shell Material | Aluminum Alloy | ||

| Color | Silver | ||

| Product description | IO-LINK master module | ||

| 8 Class A port | |||

| IP67 protection class | |||

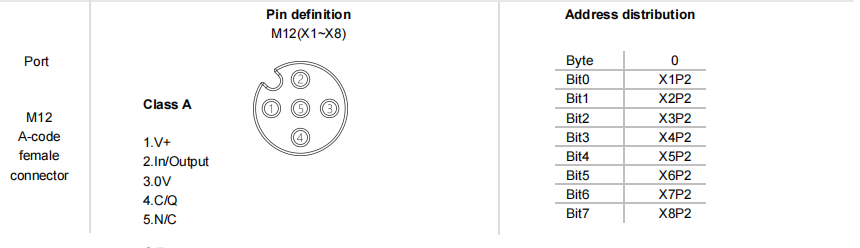

| I/O connection mode | M12, 5pin hole holder, A code | ||

| IO-Link master parameters | |||

| Number of master stations | The maximum configurable 8 ports | ||

| Master connection mode | M12, 5-core, A-code, female head | ||

| lO-link version | V1.1.2 | ||

| Communication rate | COM1:4.8KBps | ||

| COM2;38.4KBps | |||

| COM3:230.4KBps | |||

| The port voltage is L+ | type.24VDC(via US) | ||

| The port current is L+ | 2A(via US) | ||

| ClassB auxiliary voltage | - | ||

| ClassB auxiliary voltage | - | ||

| Class A | 8port ,X1.….X8 | ||

| Class B | - | ||

| Master-slave communication distance | ≤20 meters | ||

| Master-master communication distance | ≤100meters | ||

| Digital input and output parameters | |||

| Number of inputs | 8 way, adaptive | ||

| Input port location | X1…X8 | ||

| Polarity of input | PNP | ||

| Signal "0" voltage | -0.3…5VDC | ||

| Signal "1" voltage | 12…30VDC | ||

| incoming current | type.5mA(via US) | ||

| Number of outputs | 8 way, adaptive | ||

| Output port location | X1…X8 | ||

| Polarity of input | PNP | ||

| current output | Single channel 2A(via UA) | ||

| Port protection | Power short circuit protection, power supply port overload protection | ||

| Pin definition | |||

| |||

1.Complex Assembly and Testing Workstation

Scenario: An automotive engine component assembly station requires multiple tightening shafts, vision sensors, leak detection sensors, component presence/absence detection sensors, and positioning cylinders.

Application: An 8-port master station can centrally connect all IO-Link devices. The PLC can monitor the torque curve of each tightening shaft in real time, receive leak detection pressure values, and manage the parameters of all sensors. Single-point fault diagnosis makes maintenance extremely fast.

2. Intelligent Packaging and Material Handling Unit

Scenario: The packaging machine needs to control multiple servo-driven filling heads (connected to the servo drives via IO-Link), photoelectric/ultrasonic sensors for detecting material level, and pneumatic gripper valve assemblies.

Application: The master station sends speed/position parameters to each servo drive and collects a large amount of analog data from sensors (such as material level height). High-density ports meet the IO needs of complex machines.

Assembly and Testing Workstation

Intelligent Packaging and Material Handling Unit

1.Complex Assembly and Testing Workstation

Scenario: An automotive engine component assembly station requires multiple tightening shafts, vision sensors, leak detection sensors, component presence/absence detection sensors, and positioning cylinders.

Application: An 8-port master station can centrally connect all IO-Link devices. The PLC can monitor the torque curve of each tightening shaft in real time, receive leak detection pressure values, and manage the parameters of all sensors. Single-point fault diagnosis makes maintenance extremely fast.

2. Intelligent Packaging and Material Handling Unit

Scenario: The packaging machine needs to control multiple servo-driven filling heads (connected to the servo drives via IO-Link), photoelectric/ultrasonic sensors for detecting material level, and pneumatic gripper valve assemblies.

Application: The master station sends speed/position parameters to each servo drive and collects a large amount of analog data from sensors (such as material level height). High-density ports meet the IO needs of complex machines.

Assembly and Testing Workstation

Intelligent Packaging and Material Handling Unit