In the high-precision and high-complexity production environment of semiconductor manufacturing, the accuracy of information traceability and the automation of production processes directly affect the yield and efficiency; traditional manual operation methods (such as manually triggering ID reading after loading) are not only inefficient, but also have the risk of data errors.

★ Data delays and errors caused by manual intervention

★ Incomplete traceability of wafer processing information, affecting process optimization and abnormal analysis

★ Inconsistent communication protocols between devices, and prominent information island problems

Semiconductor RFID intelligent traceability system

Build a fully automated data link through SECS/SEMI standard protocols, combined with high-performance RFID technology, to achieve real-time tracking, data transparency and intelligent decision-making of the entire wafer production process.

Semiconductor RFID application solution architecture diagram

1. Connect RFID, IO module, Sensor and LED tricolor light;

2. Place the wafer box with capsule on the loadport machine;

3. After the machine pressure sensor senses it, the input end of the IO module is triggered;

4. After the RFID control box senses the input of the IO module, it actively reads the ID of the

wafer box capsule and reports it to the EAP system after successful reading.

Help the semiconductor industry to achieve refined management

Improve yield: reduce human errors and ensure 100% traceability of process data.

Reducing costs and increasing efficiency: fully automated data collection, reducing labor costs, and accelerating production rhythm.

Intelligent decision-making: real-time data dashboards help process optimization and predictive maintenance.

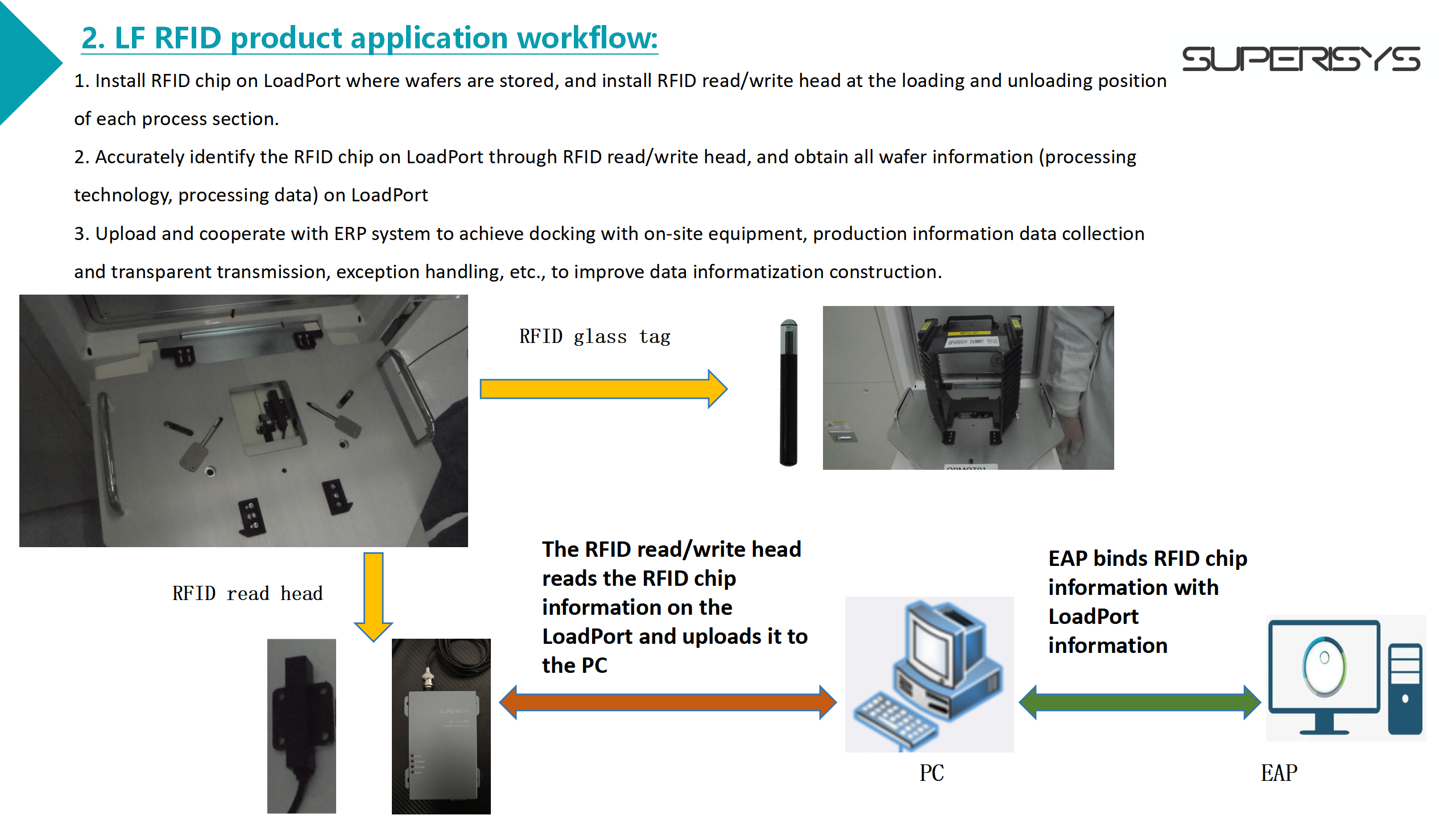

1. Accurate identification, active reporting

Integrate industrial-grade RFID tags in LoadPort

(RF-LT-DR2B), cooperate with high-sensitivity read/write heads (RF-LC12097) in each process section, and realize automatic reporting of ID when the wafer box is in place, completely replacing manual triggering;

Millisecond response to ensure data real-time and accuracy.

2 Full-process traceability, data closed loop

Real-time collection of wafer processing technology and process data, and seamless connection with MES/ERP system to build a complete production information database;

Support forward traceability (current process status) and reverse traceability (historical process path) to help quickly locate the root cause of abnormalities.

3. SECS/SEMI standardized integration

Based on SECS/GEM protocol, efficient communication between devices is achieved, information silos are broken, and system compatibility and scalability are improved;

Comply with SEMI international standards to ensure the universality and reliability of the solution in the semiconductor industry.