RF-HZ80-TP

Superisys

| Availability: | |

|---|---|

| Quantity: | |

High-Speed & Compact Design for Flexible Automation

Combining high-speed data transmission with a compact form factor, the HF 80 Series is engineered for integration into assembly lines, flexible manufacturing systems, and automated applications where space efficiency and reliable performance are critical.

Comprehensive Status Monitoring & Diagnostics

Equipped with advanced real-time status indication and diagnostic functions, the reader enables quick troubleshooting and predictive maintenance, minimizing downtime and enhancing operational reliability.

Cloud-Ready for Production Transparency

By delivering structured data to cloud-based applications, the HF 80 facilitates real-time production visibility, traceability, and data-driven process optimization across the manufacturing workflow.

Multi-Interface Connectivity for Seamless Integration

Supporting industry-standard communication interfaces including RS485, Ethernet, and IO-Link, the reader ensures flexible and straightforward integration into diverse industrial automation environments and existing infrastructure.

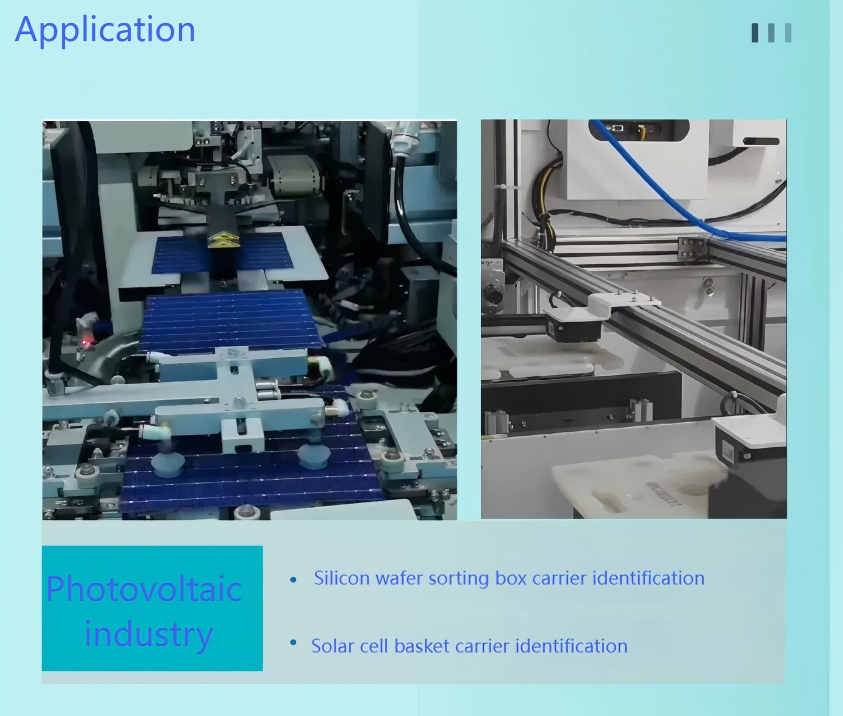

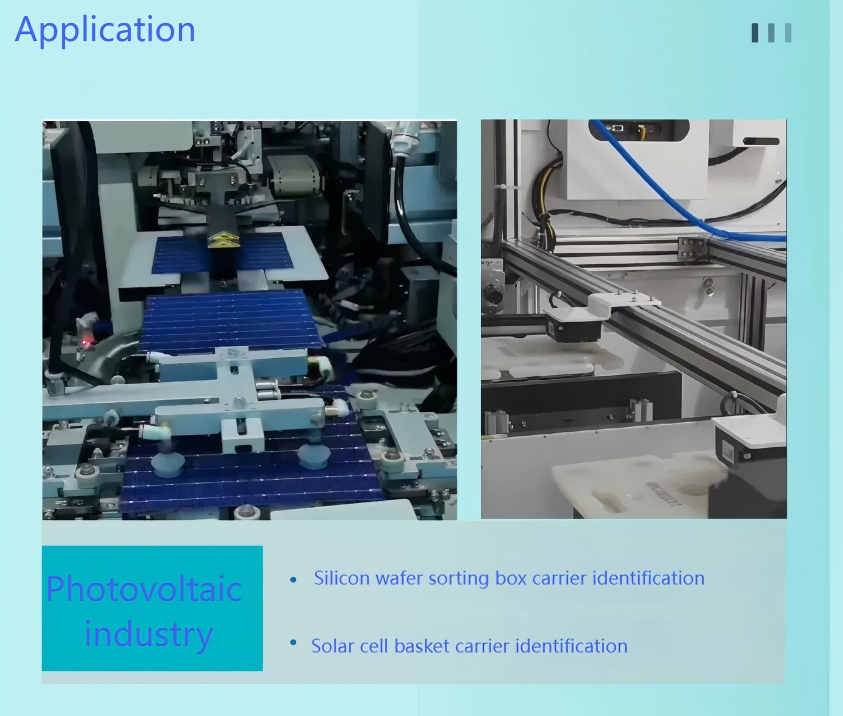

New Energy

Photovoltaic Industry - Silicon Wafer Sorting Box Tray Identification

Processing:

Tag Selection: Install a high-temperature, chemically resistant HF RFID tag (typically conforming to ISO 15693 standard, with a moderate reading distance suitable for dense environments) on each sorting box tray.

Data Writing: When silicon wafers are sorted and loaded into the trays, key information is written to the tray tag using an HF80 reader(Cubic 13.56Mhz HF rfid read/write head), including: batch number, silicon wafer type (P-type/N-type, resistivity), specifications (size, thickness), quantity, sorting grade (A-grade, B-grade), production timeline, and next process instruction.

Benefit:

Quality Traceability: When defects are found during subsequent cell inspection, the tray tag information allows for rapid reverse tracing back to the original batch, sorting machine, and production time of the problematic silicon wafer, greatly reducing the scope of investigation.

Work-in-Process Management: Real-time monitoring of the location and status of each batch of silicon wafers on the production line optimizes production scheduling.

Core Values:

"Zero" Errors: Eliminates human error in recording and batch mixing.

End-to-End Transparency: Enables end-to-end digital tracking of silicon wafers from sorting to cell manufacturing.

Improved Efficiency: Automatic identification and data integration reduce manual scanning and confirmation time.

High-Speed & Compact Design for Flexible Automation

Combining high-speed data transmission with a compact form factor, the HF 80 Series is engineered for integration into assembly lines, flexible manufacturing systems, and automated applications where space efficiency and reliable performance are critical.

Comprehensive Status Monitoring & Diagnostics

Equipped with advanced real-time status indication and diagnostic functions, the reader enables quick troubleshooting and predictive maintenance, minimizing downtime and enhancing operational reliability.

Cloud-Ready for Production Transparency

By delivering structured data to cloud-based applications, the HF 80 facilitates real-time production visibility, traceability, and data-driven process optimization across the manufacturing workflow.

Multi-Interface Connectivity for Seamless Integration

Supporting industry-standard communication interfaces including RS485, Ethernet, and IO-Link, the reader ensures flexible and straightforward integration into diverse industrial automation environments and existing infrastructure.

New Energy

Photovoltaic Industry - Silicon Wafer Sorting Box Tray Identification

Processing:

Tag Selection: Install a high-temperature, chemically resistant HF RFID tag (typically conforming to ISO 15693 standard, with a moderate reading distance suitable for dense environments) on each sorting box tray.

Data Writing: When silicon wafers are sorted and loaded into the trays, key information is written to the tray tag using an HF80 reader(Cubic 13.56Mhz HF rfid read/write head), including: batch number, silicon wafer type (P-type/N-type, resistivity), specifications (size, thickness), quantity, sorting grade (A-grade, B-grade), production timeline, and next process instruction.

Benefit:

Quality Traceability: When defects are found during subsequent cell inspection, the tray tag information allows for rapid reverse tracing back to the original batch, sorting machine, and production time of the problematic silicon wafer, greatly reducing the scope of investigation.

Work-in-Process Management: Real-time monitoring of the location and status of each batch of silicon wafers on the production line optimizes production scheduling.

Core Values:

"Zero" Errors: Eliminates human error in recording and batch mixing.

End-to-End Transparency: Enables end-to-end digital tracking of silicon wafers from sorting to cell manufacturing.

Improved Efficiency: Automatic identification and data integration reduce manual scanning and confirmation time.

| product model | RF-HZ80-R4 | RF-HZ80-TP | RF-HZ80-IOL |

| wireless protocol | ISO 15693, | ||

| working frequency | 13.56MHz | ||

| output power | 27.5dBm | ||

| wireless speed | 26.48Kbit/s | ||

| Read distance | 0~110(related to labels) | ||

| communication interface | RS485 | Ethernet | IO-Link |

| communication protocol | MODBUS RTU | MODBUS TCP | IO-Link V1.1 |

| Communication rate | 9600 ~ 115200bit/s | 10/100M Adaptive | 230.4kbps |

| Supply voltage | 9~30VDC | ||

| Average current | <0.07A@24VDC | ||

| pilot lamp | 5 LED indicators | ||

| Form factor | 80x80x40mm | ||

| Product Interface | M12 Acode 5pin male | M12 Acode 8pin male | M12 Acode 5pin male |

| Fixed type | 2pcs M5 Screw holes | ||

| Housing material | PC+ABS | ||

| Shell color | black | ||

| Total weight | About 260g | ||

| Operating temperature | -25℃~70℃ | ||

| Storage temperature | -25℃~85℃ | ||

| humidity | 5%~95%RH(No condensation) | ||

| Waterproof and dustproof rating | IP67, EN 60529 | ||

| Vibration resistant | 2 mm (f= 5…29.5 Hz ) , EN 60068-2-6 7 gn (f= 29.5…150 Hz) , EN 60068-2-6 | ||

| Conducted immunity (CS) | 3V, over A class (including main frequency) 10V, over A class (except main frequency) | ||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, over class A Air discharge, 15KV, over class A IEC 61000-4-2 | ||

| Certificate | CE FCC | ||

| ROHS directive | 2011/65/EU,2015/863/EU | ||

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 1-2 work days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| product model | RF-HZ80-R4 | RF-HZ80-TP | RF-HZ80-IOL |

| wireless protocol | ISO 15693, | ||

| working frequency | 13.56MHz | ||

| output power | 27.5dBm | ||

| wireless speed | 26.48Kbit/s | ||

| Read distance | 0~110(related to labels) | ||

| communication interface | RS485 | Ethernet | IO-Link |

| communication protocol | MODBUS RTU | MODBUS TCP | IO-Link V1.1 |

| Communication rate | 9600 ~ 115200bit/s | 10/100M Adaptive | 230.4kbps |

| Supply voltage | 9~30VDC | ||

| Average current | <0.07A@24VDC | ||

| pilot lamp | 5 LED indicators | ||

| Form factor | 80x80x40mm | ||

| Product Interface | M12 Acode 5pin male | M12 Acode 8pin male | M12 Acode 5pin male |

| Fixed type | 2pcs M5 Screw holes | ||

| Housing material | PC+ABS | ||

| Shell color | black | ||

| Total weight | About 260g | ||

| Operating temperature | -25℃~70℃ | ||

| Storage temperature | -25℃~85℃ | ||

| humidity | 5%~95%RH(No condensation) | ||

| Waterproof and dustproof rating | IP67, EN 60529 | ||

| Vibration resistant | 2 mm (f= 5…29.5 Hz ) , EN 60068-2-6 7 gn (f= 29.5…150 Hz) , EN 60068-2-6 | ||

| Conducted immunity (CS) | 3V, over A class (including main frequency) 10V, over A class (except main frequency) | ||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, over class A Air discharge, 15KV, over class A IEC 61000-4-2 | ||

| Certificate | CE FCC | ||

| ROHS directive | 2011/65/EU,2015/863/EU | ||

| Parameter | Specification |

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 1-2 work days |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |