RF-HY18RL

Superisys

| Availability: | |

|---|---|

| Quantity: | |

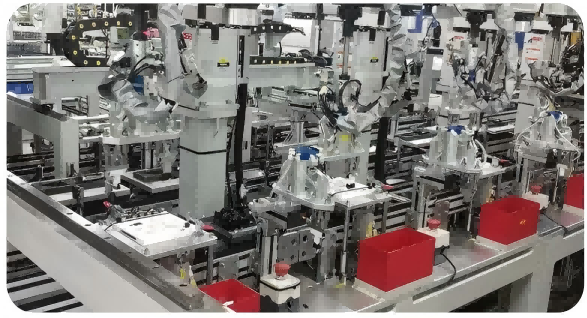

By installing RF-HY18R RFID readers on CNC machine tools, CNC machining centers, or tool management cabinets, seamless integration with the equipment's control system is achieved. When a tool enters the equipment, the reader automatically reads the tool information from the embedded RF-HZMTY80M code carrier on the tool and transmits the data to the control system. The control system then automatically retrieves machining parameters or updates the tool status based on the read information.

The system automatically tracks tool usage frequency and time, proactively issuing alerts when tools reach the end of their lifespan or require calibration, thus preventing quality incidents caused by tool failure.

Anti-theft and Efficiency: Reduces tool loss and search time, enabling refined asset management.

Material Error Prevention and Binding:

At workstations where critical components (such as camera modules, CPUs, and batteries) need to be installed, material boxes or feeders are also labeled.

The system compares the carrier label (product identity) with the material label (part identity). Only when a match is found is material retrieval and installation permitted, and a record is made in the background stating "A product with a certain serial number used a part with a certain serial number," achieving precise traceability throughout the entire supply chain.

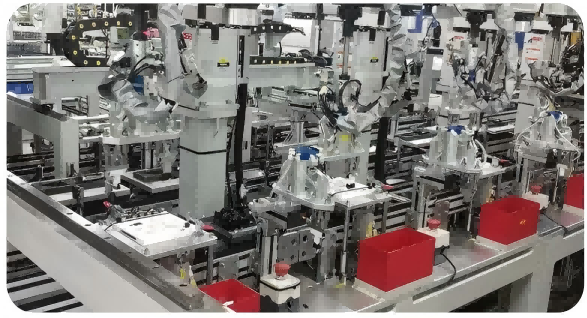

By installing RF-HY18R RFID readers on CNC machine tools, CNC machining centers, or tool management cabinets, seamless integration with the equipment's control system is achieved. When a tool enters the equipment, the reader automatically reads the tool information from the embedded RF-HZMTY80M code carrier on the tool and transmits the data to the control system. The control system then automatically retrieves machining parameters or updates the tool status based on the read information.

The system automatically tracks tool usage frequency and time, proactively issuing alerts when tools reach the end of their lifespan or require calibration, thus preventing quality incidents caused by tool failure.

Anti-theft and Efficiency: Reduces tool loss and search time, enabling refined asset management.

Material Error Prevention and Binding:

At workstations where critical components (such as camera modules, CPUs, and batteries) need to be installed, material boxes or feeders are also labeled.

The system compares the carrier label (product identity) with the material label (part identity). Only when a match is found is material retrieval and installation permitted, and a record is made in the background stating "A product with a certain serial number used a part with a certain serial number," achieving precise traceability throughout the entire supply chain.

| product model | RF-HY18RL-R4 | RF-HY18RL-R2 | RF-HY18RL-IOL |

| wireless protocol | ISO15693 | ||

| Operating frequency | 13.56MHz | ||

| output power | 27.5dBm | ||

| Distance | 0~60mm(Related to the loaded code body) | ||

| wireless speed | 26.48kbps | ||

| communication interface | RS485 | RS232 | IO LINK |

| communication protocol | MODBUS RTU | IO LINK V1.1 | |

| Communication rate | 9600~115200bit/s | 230.4kbps | |

| mains input | 9-30VDC | ||

| average current | <0.07A@24VDC | ||

| indicator light | 1 LED indicator | ||

| boundary dimension | M18*92mm | ||

| Product interface | M12 Acode 4PIN male head | ||

| Installation | Screwing with M18*1.0 | ||

| Material | Brass plated with nickel +ABS | ||

| Shell color | Silver + Black | ||

| total weight | 50g | ||

| operating temperature | ~25℃~+70℃ | ||

| storage temperature | ~25℃~+85℃ | ||

| humidity | 5%~95%RH(without condensation) | ||

| Waterproof and dustproof grade | IP67, EN 60529 | ||

| Resistance to vibration | 2 mm (f= 5…29.5 Hz ) | ||

| EN 60068-2-6 | |||

| 7 gn (f= 29.5…150 Hz) | |||

| EN 60068-2-6 | |||

| Conduction immunity (CS) | 3V, Class A (including main frequency) | ||

| 10V, Class A (except main frequency) | |||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, Class A air discharge, | ||

| 15KV, class A IEC61000-4-2 | |||

| FCC | |||

| ROHS instruct | 2011/65/EU,2015/863/EU | ||

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 5-8 Work Days |

| Stock | In Stock |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |

| product model | RF-HY18RL-R4 | RF-HY18RL-R2 | RF-HY18RL-IOL |

| wireless protocol | ISO15693 | ||

| Operating frequency | 13.56MHz | ||

| output power | 27.5dBm | ||

| Distance | 0~60mm(Related to the loaded code body) | ||

| wireless speed | 26.48kbps | ||

| communication interface | RS485 | RS232 | IO LINK |

| communication protocol | MODBUS RTU | IO LINK V1.1 | |

| Communication rate | 9600~115200bit/s | 230.4kbps | |

| mains input | 9-30VDC | ||

| average current | <0.07A@24VDC | ||

| indicator light | 1 LED indicator | ||

| boundary dimension | M18*92mm | ||

| Product interface | M12 Acode 4PIN male head | ||

| Installation | Screwing with M18*1.0 | ||

| Material | Brass plated with nickel +ABS | ||

| Shell color | Silver + Black | ||

| total weight | 50g | ||

| operating temperature | ~25℃~+70℃ | ||

| storage temperature | ~25℃~+85℃ | ||

| humidity | 5%~95%RH(without condensation) | ||

| Waterproof and dustproof grade | IP67, EN 60529 | ||

| Resistance to vibration | 2 mm (f= 5…29.5 Hz ) | ||

| EN 60068-2-6 | |||

| 7 gn (f= 29.5…150 Hz) | |||

| EN 60068-2-6 | |||

| Conduction immunity (CS) | 3V, Class A (including main frequency) | ||

| 10V, Class A (except main frequency) | |||

| Electrostatic discharge immunity ESD | Contact discharge, 8KV, Class A air discharge, | ||

| 15KV, class A IEC61000-4-2 | |||

| FCC | |||

| ROHS instruct | 2011/65/EU,2015/863/EU | ||

| Minimum Order Quantity | one |

| Price | receive bargaining |

| Delivery Time | 5-8 Work Days |

| Stock | In Stock |

| Payment Terms | T/T, Western Union |

| Supply Ability | 1000 per day |