In the era of intelligent and connected vehicles, automotive Bluetooth modules play a critical role in in-vehicle infotainment and connectivity systems. Their performance stability and consistency directly impact overall vehicle quality.

However, ensuring precise process control, zero-defect production, and full lifecycle traceability remains a major challenge in high-precision automotive electronics manufacturing.

Superisys Industrial RFID solutions deliver an automated data acquisition and closed-loop quality management system, enabling complete traceability from production to warehousing and driving a new standard of efficiency and reliability for automotive Bluetooth module manufacturing.

The manufacturing process of automotive Bluetooth modules is highly complex and involves multiple critical steps, including wire bonding, functional testing, RF performance validation, and calibration. Traditional production management methods often face the following challenges:

Fragmented process data and heavy reliance on manual recording

Limited traceability across production stages

Delayed detection and isolation of defective products

Incompatibility between existing equipment and digital management systems

These issues increase quality risks, reduce production efficiency, and make it difficult to meet the strict traceability requirements of the automotive industry.

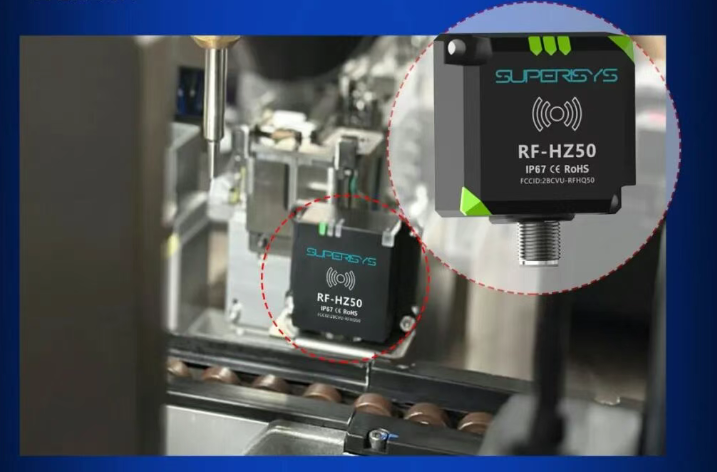

Superisys deploys industrial-grade RFID readers at key equipment such as wire bonding machines and test stations, while high-precision RFID data carriers are embedded into tray pallets used for module transportation.

This enables:

Automatic Data Collection

As each Bluetooth module moves through every production step, the system automatically records key parameters such as bonding data, RF test results, and calibration information

Real-Time Defect Interception

If a test result fails to meet specifications, the system instantly flags the product and prevents it from entering the next process

Full Lifecycle Traceability

Each module’s complete manufacturing history, quality status, and test records are securely bound to its RFID data carrier, enabling end-to-end traceability.

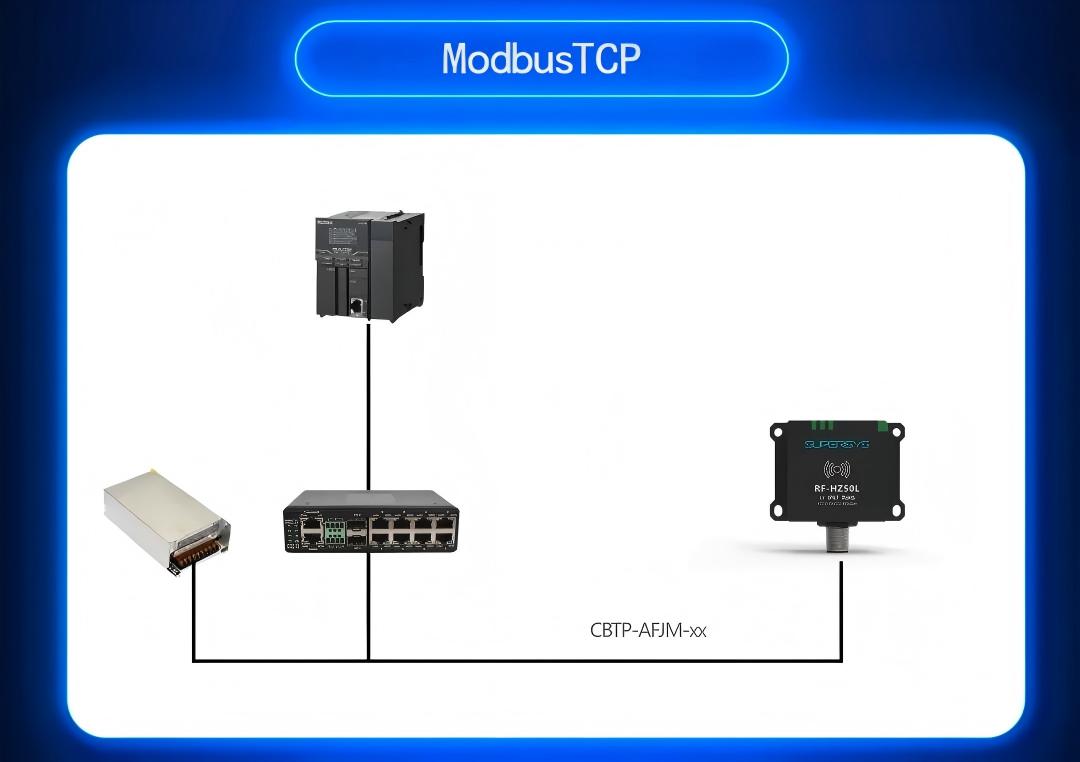

Superisys RFID systems support multiple industrial communication interfaces, including:

Serial communication (RS232 / RS485)

Ethernet (TCP/IP)

Seamless integration with PLCs, MES, and test systems

This flexibility ensures fast deployment, smooth system integration, and maximum protection of existing production investments, without disrupting current workflows.