Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

RFID (Radio Frequency Identification) technology is revolutionizing the lithium battery manufacturing industry by boosting production efficiency, ensuring quality, and enabling smart automation. As industries move toward Industry 4.0, RFID solutions are playing a pivotal role in transforming manufacturing processes.

Superisys (Wuhan) Intelligent Technology Co., Ltd.provides high-performance RFID solutions for industries like lithium battery manufacturing. With over 15 years of experience, we offer OEM and ODM services, delivering reliable RFID products that meet international standards like FCC, CE, and RoHS. Superisys is dedicated to empowering automation integrators, service providers, and engineers with cutting-edge technology.

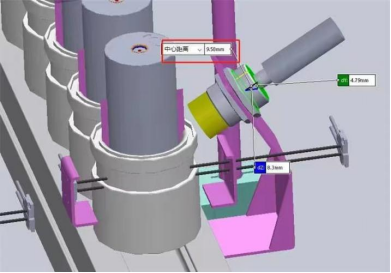

Challenge: Tracking components in an 4680 battery production line.

Solution: RFID tags are embedded in battery cups. RFID readers at key points scan the tags, and the data is integrated with the Manufacturing Execution System (MES) to track battery parameters like voltage and performance. This allows for precise monitoring of production from start to finish.

Superisys Products Used:

HY30R-TP

HZ40L-TP

HZMTY700-112

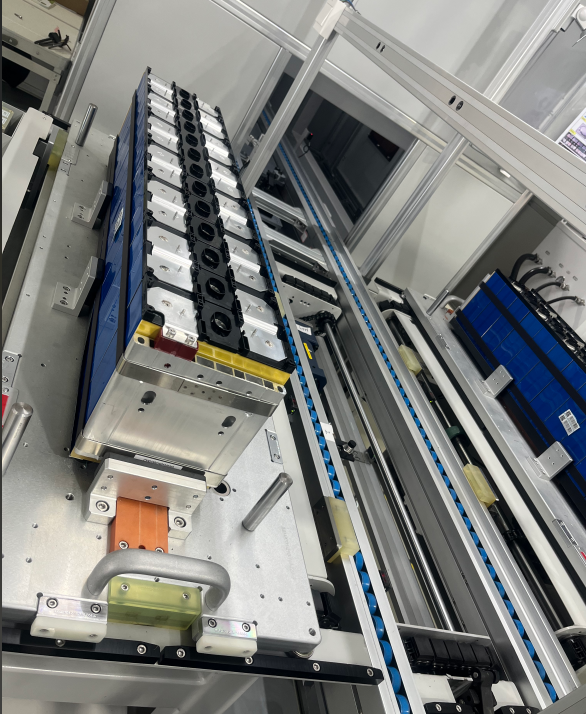

Challenge: Real-time monitoring of battery cells during assembly.

Solution: RFID tags are embedded in carriers that move the cells through the production line. RFID readers scan the tags to collect data on the battery’s key parameters. This ensures quality control and full traceability of each cell.

Superisys Products Used:

HY18R-R4

IACM-P4-EN

HZMTY300-2K

Automation and Efficiency:

RFID ensures real-time tracking of production, reducing manual errors and enhancing automation.

Data Traceability:

RFID tags allow for quick identification and resolution of quality issues, ensuring efficient problem-solving.

Optimized Production:

With RFID, manufacturers can analyze data to streamline production processes, reduce costs, and improve efficiency.

Quality Assurance:

RFID technology provides complete traceability, ensuring that any quality issues can be quickly traced back to the source.

RFID is helping the lithium battery industry move toward a fully automated production system. By adopting RFID, manufacturers can achieve smarter, more efficient operations, which aligns with the principles of Industry 4.0.

RFID technology is transforming lithium battery manufacturing, offering solutions that improve production efficiency, quality control, and traceability. Superisys leads the way in providing advanced RFID solutions that help businesses implement smart, automated systems. With our reliable and customizable products, we help automation integrators, service providers, and engineers stay ahead in the competitive market.